Ohmic heating, also called Joule heating, is one of the few food processing methods that uses electricity. James Prescott Joule discovered that electricity gives off heat, and this heat is produced from resistance (ohms) in 1841. To put it simply, electricity is converted into heat energy. This discovery has led to believe that this process can be used to process and preserve food.

This has turned into fruition when Ohmic heating was used to pasteurize milk in the late 19th century. The process involved flowing milk between two plates of different electric voltages. At the turn of the 20th century, progress in Ohmic heating was considerably limited though.

This was due to various reasons, mainly technological constraints (lack of suitable electrode materials), lack of the understanding of the process, and financial considerations. In 1930s, the process was called “Electro-Pure”. In the 1950s, a process of sterilizing milk using Ohmic heating was developed. However, the process was discontinued because of the high operational costs and the excessive use of electricity.

Interest in Ohmic was revisited in the 1980s because there was a need for a process that could efficiently sterilize liquid–large particle mixtures. Today, Ohmic heating has become an attractive option for food manufacturing. This is in large part of the unending research and study about the technology.

Let’s discuss Ohmic heating further.

Table of Contents

What is Ohmic heating?

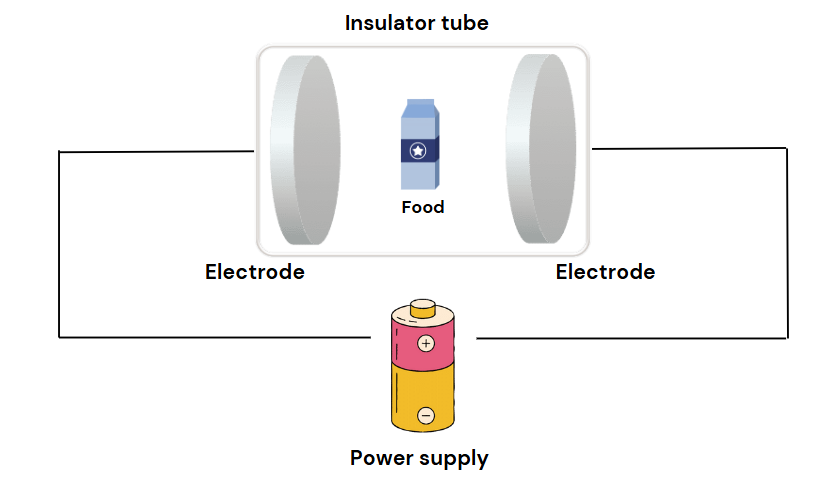

Ohmic heating is a food process wherein electric current is converted into heat energy to heat the food. It is also known as Joule heating, electrical resistance heating or resistance heating, and electro-heating. A Ohmic heating device commonly consists of a power source, an electrode, and a way to contain the sample, a vessel or tube, for example.

Ohmic is performed by passing alternating current (AC) or direct current (DC) to the food material placed between electrodes. As the electricity hits the food, salts, water and other components resist this energy and generates heat.

This food process is based on the principle of electrical resistance. Electrical resistance is the measure of how resistant a material is to the flow of electric current. In the case of Ohmic heating, the food material is the electrical resistor. The resistance depends on various factors, including the composition of the food, and the amount of moisture present.

Because of this resistance, the electric energy is dissipated and converted into heat. This heat generation is rapid that allows quicker and uniform heating of food than in thermal-based food processes. Ohmic heating is particularly effective for liquid–particle mixtures as they allow uniform heat transfer.

Ohmic heating vs conventional heating methods

Conventional thermal processing methods such as boiling, sterilization, and canning have been known to cause product quality degradation because of slow convection and conduction heat transfer.

Slow heat transfers in conventional heat treatments are fully known in the food industry. In canning, food is heated by conduction, wherein heat is transferred from one material to another. In the case of canning, heat is transferred from the can to the food. This heat transfer is slow, especially if the can is considerably larger or the food is densely packed inside.

This is where Ohmic heating is a much better option. With Ohmic, the entire food mass can be heated volumetrically. It is possible to heat large portion of food by up to 1 in.3. And since Ohmic heating can heat food rapidly, it can transfer heat to the inner portion without difficulty.

This is unlike conventional methods that sometimes overprocess the surrounding liquid portion of the food being heated as it transfers heat to the inner portion. This uneven heating diminishes quality.

In nutrient retention for example, it has been studied that food that has undergone conventional heat treatments contain lower nutrients, particularly heat-sensitive ones.

One of the findings in this study is the reduction vitamin C in food processed under Ohmic and conventional heating. In conventional heating, the product’s vitamin C reduced by 13.58%. Ohmic heating, on the other hand, was not that different from unheated sample. Another study found heating under Ohmic helps retain significantly higher antioxidant activities and essential minerals essential minerals calcium, potassium, and phosphorus.

This just suggests that Ohmic heating is better at preserving food quality, especially nutrients, than conventional methods.

Uses and applications

The first use of Ohmic heating was for sterilizing milk in the 19th century. Since then, its usage than expanded to various sectors in the food industry. It is now also used for food items such as fruit juices, purees, meat, canned goods, and vegetables.

Let’s briefly discuss some of the processes Ohmic heating is used for.

Thermal processing

Pasteurization and sterilization have long been used for processing liquid like milk and fruit juices. Pasteurization involves temperatures that destroys and reduce the levels of spoilage microorganisms, whereas sterilization destroys all microorganisms, including beneficial ones (probiotics, for example).

You might also like: Are Fresh Foods Superior To Canned And Frozen?

Integrating Ohmic heating with these thermal processes helps rapid and uniform heating to maintain product quality. In the United States, Ohmic heating is used to produce liquid egg product.

Fermentation

Fermentation is an anaerobic process that uses microorganisms to convert carbohydrates such as sugar into alcohol. Examples of fermented products includes kimchi, yogurt, and wine.

The application of Ohmic heating in fermentation has been less common than when used with thermal processes. One beneficial use of it in fermentation is the reduction of acidity in cocoa and coffee beans. While acidity may be desirable to some varieties of coffee, reducing its levels in many varieties often results in a smoother and rounded flavor. Arabica coffee is one example of coffee that naturally contain high acidity.

This study proved that using Ohmic heating can effectively reduce this acidity to a more desirable level. The time and temperature variations used in the study resulted in acid levels between 0.18% and 0.73%.

Thawing

Food thawing may be a relatively simple step in food preparation. But doing it in a much better way can help food processors save resources and retain quality. In most cases, there would be moisture loss or drip loss. This is evident when the food is drier. Drip loss is commonly associated with meat, seafood, fruits, and vegetables.

Drip loss occurs because the ice crystals that ruptured that cell walls turns into water and escapes from the food. There is more drip loss if air thawing is done because the process is very slow. With Ohmic heating, thawing is rapid because the heat is generated from the food itself, instead from the surface inward.

Another benefit of Ohmic heating for thawing is that there is not a need for water. Hence, no wastewater is generated. This also saves resource and operating cost.

Blanching

Similar to thawing, blanching may also result in moisture loss. However, the mechanism of how it occurs is different. With blanching, the elevated temperature ruptures the cell wall of the food that allows the water to escape and nutrients to leech into the blanching water.

With Ohmic heating, it is possible to reduce or prevent moisture loss and leeching. Its rapid heat generation allows uniform heating and prevents overcooking of the surface. A study found that blanching with Ohmic heating also removes the need of cutting (a process that is commonly done prior to blanching) large pieces of food, especially vegetables. The reason here is uniform and rapid heating that traditional blanching cannot achieve. This particularly important for delicate vegetables.

Extraction

Uneven temperatures can also lead to inefficient extraction of certain components from food materials. Examples of extraction are juicing from fruits, soymilk from soybeans, and beet dye from beets.

Traditional extraction methods apply heat from the outside to the inside of the sample. Since this manner of heat transfer is relatively slow, there is an extended processing time. Not only this affects the yield, it also affects the quality of extraction. This is especially true if what involved in the extraction are heat-sensitive compounds like vitamins.

With Ohmic heating, the quality of extract is better preserved. This statement is demonstrated in this study of Ohmic heating-assisted extraction of anthocyanins from black rice bran. Anthocyanins are natural pigments responsible for the color of eggplants, blueberries, purple grapes, and cherries. Anthocyanins are heat sensitive. But with Ohmic heating used in the study, the method had better colorant yield, as well as bioactive compound activity.

References:

V. Vaclavik, E. Christian (2014). Essentials of Food Science (4th edition). Springer.

S. Rahman (2007). Handbook of Food Preservation (2nd edition). CRC Press

P. Fellows (2000). Food Processing Technology (2nd edition). CRC Press

P. Zeuthen, L. Bogh-Sorensen (2003). Food Preservation Techniques. CRC Press