For the most of us, whenever we hear the words “bacteria”, “fungi” or “microorganisms”, the first things that come to mind are negative things such as diseases. Well, it is definitely true that there microorganisms that do us harm. But not all the time. Let’s talk about Escherichia coli (E. coli) for example. One particular strain of E. coli is O157:H7. Someone who ingested food that is contaminated with this strain of E. coli may experience food poisoning with severe symptoms. But for most of the time, E. coli does that cause harm or adverse health effects. In fact, this bacteria lives in our intestines and those of animals.

The negative connotations associated with microorganisms is undeserving. And on the contrary, many of them are beneficial in different fields or industries. In medicine, without microbes, we would be able to produce vaccines and antibiotic. Soil microbes help farmers recycle plant materials and decompose organic matter.

In the food industry, a lot of food products that we enjoy now would not have existed without them. One species of yeast that we have worked with for thousands of years is Saccharomyces cerevisiae. This fungus is one of the most important in the food industry. It has been used extensively in the manufacture of fermented beverages such as wine and beer, distilled beverages such as vodka and rum, and baked goods. But the strains of Saccharomyces cerevisiae involved in the manufacture of these products vary tremendously.

Let’s discuss further.

WHAT IS SACCHAROMYCES CEREVISIAE?

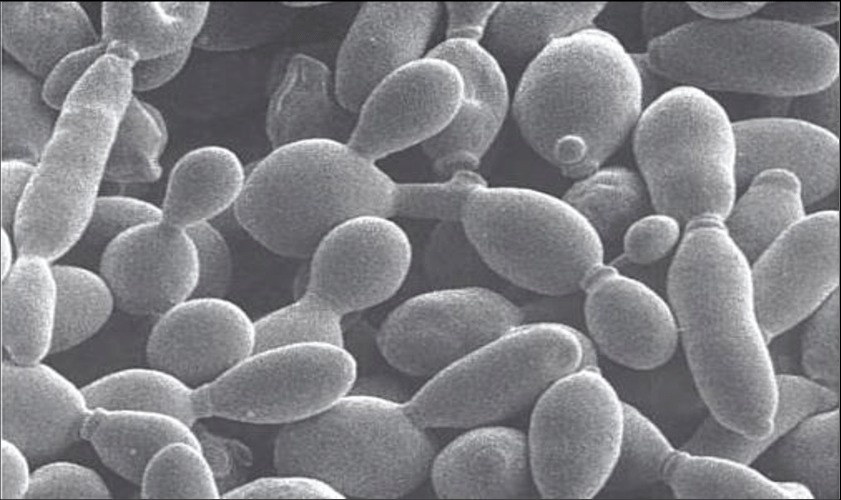

Like other species of yeasts, Saccharomyces cerevisiae is a eukaryotic, unicellular microorganism. The cells can exist in two forms: haploid or diploid. Most cells exist in diploid form, in which the cells are ellipsoid-shaped with a diameter of 5-6um, Cells in haploid form are spherical with a diameter of 4um.

Cells reproduce both sexually and asexually.

More often, S. cerevisiae reproduce asexually. In a process called budding, a haploid cell undergoes mitosis, forming new haploid cells or daughter cells that bud off the mother cell. The new cell grows bigger until it reaches the size of the mother cell and separates.

During sexual reproduction, two different haploid yeast cell mate, forming a diploid cell. This diploid cell then undergoes mitosis to form zygotes.

S. cerevisiae is a facultative anaerobe—it grows well aerobically and anaerobically. In nature, S. cerevisiae is commonly found in ripe fruits, particularly grapes. All strains can feed aerobically on sugars, including glucose, maltose, and trehalose, but not on disaccharide lactose and cellobiose. Anaerobically, some strains do not grow on trehalose and sucrose. Among these sugars, S. cerevisiae prefers glucose the most.

A 1977 study found out the optimum temperature for rapid growth of all strains of S. cerevisiae to be between 86 °F (30 °C) to 95 °F (35 °C).

Since it is easy to culture, S. cerevisiae is the most studied eukaryote. In fact, S. cerevisiae was the first ever eukaryote genome to be fully sequenced in 1996. The S. cerevisiae genome is made up of over 12 million base pairs and over 6000 genes, packaged in 16 chromosomes. Visit the Saccharomyces Genome Database for more on this.

APPLICATIONS OF SACCHAROMYCES CEREVISIAE IN THE FOOD INDUSTRY

As evidence suggests, we have been using yeasts to better the food that we eat. But for thousands of years, our ancestor from thousands of years ago never bothered to examine the process of leavening in bread or fermentation in beverages. And yes, people back then performed alcohol fermentation without realizing it.

But science took a huge leap in 1680 when Dutch scientist Antonie van Leeuwenhoek first observed yeast cells in beer using a microscope. And then French scientist Louis Pasteur followed that up with one of the greatest contributions in food microbiology. In 1857, he proved that yeasts, as living cells, are primarily responsible in fermentation—that they turn sugar into alcohol. He achieved this by proving that yeasts thrive with or without oxygen. He also identified that S. cerevisiae is the key microbe in wine and bread making.

You might also like: The Mold Penicillium Roqueforti And Blue Cheese

Today, Saccharomyces cerevisiae yeast has many applications in the food industry, namely brewing, baking, and winemaking.

Brewing

It is hard to pinpoint the exact origin of beer fermentation. But according to history, the oldest piece of evidence was a chemically confirmed barley beer found in modern day Iran.

Basically, beer is produced using germinated cereal grains (referred to as malt), flavoring like hops, water (which accounts for 93% of beer by weight), and yeasts. Yeasts are perhaps the most important ingredient in beer brewing. It is largely responsible for beer’s final characteristics—the alcohol content, appearance, aroma, and flavor—through a process called alcoholic fermentation.

When yeasts are added, they start feeding off the sugar available. The sugars in beers are mostly maltose, a dissacharide. The sugars consumed by yeasts are converted into alcohol and carbon dioxide. The final ethanol content by weight of beers vary from about 3% to 8%. Carbon dioxide is responsible for that fizz sound whenever we open a can of beer. However, CO2 produced during fermentation is allowed to escape. Oftentimes, brewers increase the carbonation by introducing pressurized CO2. Beer fermentation takes a week to several months to complete. This mainly depends on the type of beer (strength) and the yeast involved.

Once fermentation has finished, the beer is conditioned. This is where the yeast settles at the bottom of the fermentation tank, clarifying the beer. The yeast can be collected and reused for the next brewing process.

Around the world, there are over a hundred beer styles that exist. These include lagers, ales, and stouts. One main difference between these beers is how they are fermented. Ale beers are produced using S. cerevisiae yeast at temperatures of 53.6 °F to 64 °F. Whereas lagers are produced using Saccharomyces carlsbergensi yeast at a colder temperature of 46.4 °F to 53.6 °F. Both both ales and lager beers can be dark or light in appearance.

Baking

There are generally 3 main types of leavening agents in baked products. These include physical leaveners such as air or steam, chemical agents such as baking soda and baking powder, and biological agents such as yeast. Unsurprisingly, the species of yeasts more synonymous with baking is S. cerevisiae. This is why S. cerevisiae is also called baker’s yeast.

Occasionally, bakers use other species of yeast in baking. Saccharomyces exiguus is typically used as sourdough yeast.

Baker’s yeast come in several forms. In commercial baking, where the daily production volume is immense, cream yeast is used. Cream yeast looks similar to a yeast slurry. It is about 85% water and 15% S. cerevisiae yeast. Cream yeast only lasts for up to 10 days, so refrigeration and additional equipment during storage is necessary.

Another form of yeast widely used in commercial baking is compressed yeast. Compressed yeast is similar to cream yeast, but contains less liquid. It is generally 70% water and 30% yeast. Like cream yeast, compressed yeast has a very short life span. For this reason, compressed yeast is now less common, especially in developing countries.

Active dry yeast and instant yeast are common forms of yeast for baking at home. In many home recipes, both forms can be used interchangeably. The main difference between the two is that active dry yeast requires dehydration before use. Whereas instant yeast can be added and mixed directly with other ingredients. Instant yeasts also requires less time to rise.

One advantage of active dry yeast has a longer shelf life than other forms of yeast. It can last for a year at room temperature.

Winemaking

Wine is an alcoholic drink generally made from fermented grape juice. Like in brewing beer, the addition of S. cerevisiae yeast converts the sugar in the fruit into ethanol and carbon dioxide.

Some winemakers use wild yeast to ferment wine for more interesting complex flavors. Thousands of years ago, wines were fermented using wild or “natural” yeasts. They tend to be more active once the grapes have matured enough. However, one major flaw of using wild yeast is its unpredictable nature. And a lot of wild yeasts do not produce quality wine. Most of these yeasts belong in the Kloeckera and Candida genera.

In order to produce quality wines consistently, commercial wineries inoculate strains of S. cerevisiae yeast.

Throughout history, vintners or winemakers have used fruits (apple wine) other than grapes, vegetables, and grains (rice wine such as sake). But wine varieties made from these do not usually produce wine with qualities similar to those made from grapes. The main reason for this is that they contain less fermentable sugars and water to maintain proper fermentation.

Grapes are high in sugars. The initial sugar content of the grape juice dictates the alcohol level of the resulting wine. Unripe grapes contain predominantly glucose. Ripe grapes contain equal amount of glucose and fructose, both of which are fermentable sugars. Other sugars in the grapes in smaller amounts include pentoses, cellobiose, and galactose, all of which are unfermentable sugars.

After fermentation, the wine can have an alcohol or ethanol content between 11-13% on average. This depends on several factors such as the wine variety and the winemaker. For example, some winemakers intentionally stop the fermentation process before the yeast converts of all the sugars into alcohol. This results in a sweeter wine.

Other references

M. Shafiur Rahman (2007). Handbook of Food Preservation (2nd edition). CRC Press.

M. Wallert, K. Colabroy, B. Kelly, J. Provost (2016). The Science of Cooking: Understanding the Biology and Chemistry Behind Food and Cooking. John Wiley & Sons, Inc.

J. Jay, M. Loessner, and D. Golden (2005). Modern Food Microbiology (7th Edition). Springer

O. Zaragoza, A. Casadevall (2021), Encyclopedia of Mycology, Elsevier.