Food irradiation is commonly known as one of the many ways of prolonging the shelf life of food. However, backed by decades of research, this technology is also effective in: inhibition of sprout development in certain crops, delaying ripening in fruits, and sterilization of packaging materials, to name a few. Aside from its versatility, the operating cost, and energy requirement are relatively low, and the procedure is automatically controlled.

However, the high capital cost necessary in building an irradiation facility is holding this technology back. The initial investment cost typically ranges between $1 million up to $5 million. Another is the slow consumer acceptance due in large part of the potential negative effects. These are the reasons why food irradiation is not yet widely practiced. In fact, only 30% of all the countries worldwide have at least 1 irradiation treatment facility. While some are still in pilot stage. And to add to that, a large portion of irradiated food do not even enter international trade.

And if you are wondering, food irradiation is not a novel technology.

Table of Contents

HISTORY OF FOOD IRRADIATION

Food irradiation began in the late 19th century. In 1896, Henri Becquerel, a French physicist, accidentally discovered radioactivity. In the same year, a German medical journal published an article that described how ionizing radiation could kill pathogens and spoilage microorganisms. Then in 1905, a joint U.S.-British project released a patent describing how ionizing radiation can destroy harmful microorganisms in food. Other studies on food irradiation followed in the 20th century.

Food irradiation as a means of preservation started in the 1920s after a French scientist found out its effectiveness.

But significant developments occurred in the 1940s, when researchers believed that it could potentially help preserve food used by the military. To ensure its safety and effectiveness to preserve, researchers conducted a series of experiments with various food items like fruits, vegetables, meats, and fish.

During the 1950s to 60s, the US Army conducted research involving low and high dose irradiation of military rations. This prompted other countries to start researching and using the technology in the 1970s.

In 1958, the Food, Drug, and Cosmetic Act, which administered by the Food and Drug Administration (FDA), defined the sources of radiation for use in food processing. These are gamma rays (Cobalt-60 and Cesium-137), x-rays, and electronic beams. Gamma rays are more known as a treatment for cancer. X-rays, like we all know, is also used in processing internal structures. And electron beams are high-energy electrons propelled into the food.

Today, at least 55 countries use food irradiation, including Thailand, Bangladesh, India, Australia, New Zealand, Vietnam, Canada, and the United States. Some other countries are still at the pilot stage of food irradiation technology due in large part of the high cost necessary for building a food irradiation facility.

HOW FOOD IRRADIATION WORKS

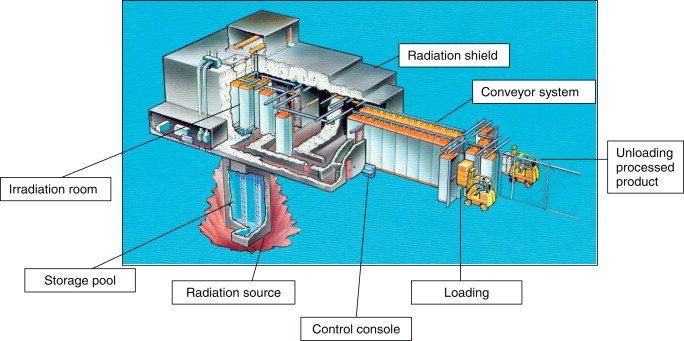

Food irradiation basically involves the use of ray of light or ionizing radiation that passes through a window. The desired dose is achieved by indirect contact with the radioactive source for a certain period of time.

There has to be a barrier to prevent the escape of ionizing radiation to utilize it to the maximum and allow a uniform dose. The barrier also protects the operator from exposure to radiation.

The most common source of radiation commercially is gamma rays because of its several advantages. First, its water solubility minimizes the environmental contamination. Second, the process requires low energy. And lastly, the change in nutritional value is comparable to other methods of conservation.

By irradiating food, the reactive ions that have been produced alter the structure of the cell membrane and affect the metabolic enzyme activity. This effectively kills or injures the microorganism. And more importantly, they render the DNA and the ribonucleic acid molecules no longer able to support reproduction by cell division.

However, like other preservation methods, the effect and strength of irradiation vary. The rate of destruction of cells depends on the rate of ions produced and interaction with the DNA. While the reduction of the number of cells depends on the radiation dose.

Some organisms have the ability to repair the damaged DNA, while some possess high resistance to radiation. Because they can form spores, bacteria such as Clostridium botulinum and Bacillus cereus are more resistant to radiation than non-spore forming and vegetative cells. The bacterium Deinococcus radiodurans is one example of microorganisms that are resistant to ionizing and ultraviolet radiation. For this reason, the resistance of the organism to radiation is one thing that dictates the radiation dose.

APPLICATION OF IRRADIATION AND DOSE RANGE

The radiation dose is the amount energy absorbed per unit weight of a substance (food). An equipment called dosimeter can measure the amount of absorbed radiation in a substance. Internationally, gray (gy) is the unit used to describe the amount of dose absorbed, while the United States, on the other hand, uses the unit rad. 1 gray is equivalent to 100 rads.

The maximum overall average dose of 10 kGy (kilogray) is adequate for most applications. However, 10 kGy is considered insufficient to reach sterility of foods that require high dose such as food for NASA and patients with weak immunity. This was covered in the report regarding the wholesomeness of food irradiation with doses above 10 kGy. The review led to the revision of the Codex General Standard.

Currently, the maximum absorbed dose delivered to a food should not exceed 10 kGy, except when necessary to achieve a legitimate technological process.

Dose levels are categorized into three:

- Low dose (< 2 kGy) – Delay of ripening in fruits and inhibition of sprouting in vegetables.

- Medium dose (1 to 10 kGy) – Reduction of microbial population (pathogens).

- High dose (>10 kGy) – Sterilization of product and packaging material.

| OBJECTIVE | EXAMPLES OF FOOD | DOSE RANGE (in kGy) |

| Control of molds | Extended storage of fresh fruits | 2-5 |

| Control of parasites | Pork | 0.1-6 |

| Destruction of pathogens | Frozen meat and poultry, seafoods, spices | 2.5-10 |

| Disinfestation | Dry foods, flour, beans, grain, fruits | 0.1-2 |

| Delay ripening and senescence | Climacteric fruits like apples and bananas | 0.30-1.5 |

| Extended chill life (0-4 °C) from 5 days to 1 month | Fresh fish, meat, and soft fruits | 2-5 |

| Inhibition of sprouting | Tubers and bulbs such as garlic, onions, potatoes | 0.1-0.2 |

| Sterilization | food for people with special diet, astronauts | 44.0 |

| Sterilization of packaging materials | Wine corks, polyolefin film | 10-60 |

OBJECTIVE OF FOOD IRRADIATION

Food irradiation is commonly associated with food preservation. By inactivating or destroying insects, molds, bacteria, and other biological contaminants, the shelf life extended. Over the years, it has also saved the food industry from massive economical losses through other purposes.

Destruction of pathogens, sterilization, and food preservation

The main use of radiation in food is to prolong the shelf life of food by preservation. Irradiation makes it possible for long-term storage of food items like meat, fish, poultry and other perishables even without refrigeration. In 1990, the FDA approved the use food irradiation to control pathogens that cause food poisoning. The below table provides the D-values of some important pathogenic bacteria.

You might also like: The 7 Most Common Disease-Causing Bacteria

| D-VALUE, IN KILOGRAY (kGy) | D-VALUE, IN KILOGRAY (kGy) | FOOD | FOOD |

| C.jejuni | 0.18 | 2-4 | Beef |

| Escherichia coli | 2-4 | 2-4 | Beef |

| L. monocytogenes | 0.45 | 2-4 | Chicken |

| Salmonella sp. | 0.38-0.77 | 0 | Chicken |

| Staphylococcus aureus | 0.36 | 0 | Chicken |

| Clostridium botulinum (spores) | 3.56 | -30 | Chicken |

Relatively low radiation doses are sufficient to destroy yeasts, molds, and non-spore forming bacteria, and therefore increase the shelf life. Bacteria that survive the irradiation process are more susceptible to high heat. Combining irradiation and heat treatment is more beneficial in reducing the microbial population.

Space foods are specially designed for astronauts while in space. One of these are foods preserved by irradiation. Typical irradiated foods served for NASA astronauts require high dose to achieve sterility. This allows them to consume food without risk of food poisoning during long travel in space.

Foods are a source of infection. For patients, even non-pathogenic microbes may cause them problems. This is especially true for neutropenic patients and those who undergo chemotherapy. Because of this, patients with weak or impaired immune system may be given sterilized food by irradiation.

Inhibition of sprouting and insect infestation

Sprouting is one of the many problems farmers face, especially during post-harvest. This is especially true for those who cultivate tubers (potatoes) and bulbs such as onions and garlic. When sprouting is beginning to manifest, the starch and protein degrades affecting the overall quality of the crop. And this eventually leads to economical loss. Before, processors relied on chemical treatment to prohibit sprout development. However, researches proved that that ionizing radiation at low doses is an effective and better way of inhibiting sprouting. The FDA approved the use of ionizing radiation to delay sprouting in white potatoes in 1964.

You might also like: The Phases Of Growth Of Bacteria (Bacterial Growth Curve)

Insect infestation is a bigger problem in farming than sprouting in certain crops. It affects a wider range of produce and these include cereals, coffee beans, grains, dried nuts, dried fruits, cereals, and spices. According to Food and Agriculture Organization (FAO), insect infestation accounts for up to 40% of the losses in global crop production annually. And to add to that, these insects usually induce food-borne diseases also. In 1963, the FDA approved the use of ionizing radiation to control insect infestation in wheat and flour. To minimize and reduce infestation, a low dose of around 0.1-2 kGy is generally sufficient to achieve this. Irradiation destroys tape worms such as Trichinella at a dose of 0.3 kGy and Toxoplasma gondii at a dose of 0.25 kGy.

Food irradiation is a good alternative to fumigants and pesticides, which are potentially hazardous to the environment. Unlike food irradiation, these chemicals usually leave residues that tend to pollute the soil, ground water, and the air. One notorious pesticide is methyl bromide, which also damages the ozone layer.

Delay of ripening and senescence

Some fruits and vegetables continue to ripen after harvest. Growers intentionally delay this process to minimize losses during transport, storage, and even after purchasing the product. Climacteric fruits and vegetables such as mangoes, apples, and tomatoes are particularly susceptible to damage. For radiation-reduced delay of ripening and senescence, producers must harvest their produce right before the onset of ripening.

For fruits, low dose is ideal. Generally, the required dose for effective suppression of ethylene production range between 0.30-1.5 kGy. However, the dose of radiation depends on the composition of the product. One reason why is tissue susceptibility. While some fruits can withstand doses of 0.6 kGy or greater, most cannot. At 0.6 kGy or higher, most fruits experience adverse effects to cellulose,hemicellulose, pectins, and starch, which may lead to softening.

This study found out that radiation dose of 0.2 kGy can effectively delay the ripening process in bananas. However, the researchers observed adverse effects such as extensive tissue damage, color change, and increased respiration rate at 0.4 kGy or more.

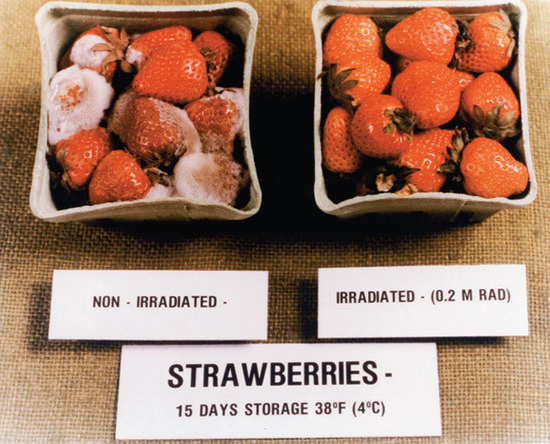

One way to effectively lower the radiation dose is by combination irradiation with modified atmosphere packaging. However, this should only be done for ripe fruits since the ripening process is inhibited. Irradiation of certain fruits and vegetables such as tomatoes and strawberries extends their shelf life 2 to 3 times, especially when the storage temperature is at 50 °F (10 °C).

Sterilization of packaging materials

Irradiated foods often come pre-packaged prior to irradiation to avoid recontamination of the produce. Radiation can penetrate the packaging material. But because of this, the integrity of the packaging might be affected, which may lead to the formation of low molecular weight hydrocarbons and halogenated polymers. For example, a radiation dose past maximum may cause browning and evolution of hydrogen chloride in PVC.

The migration of these compounds into food is likely. To prevent risks, the concerned agency (FDA in the United States), must evaluate and approve the packaging material, as well as adhesive and printing material involved before use.

It is ideal that the packaging material can withstand stress due to high radiation doses as well as low temperature (down to -40° C). This is to ensure that the material remains impermeable to moisture, microorganisms, and other contaminants.

When irradiating food packaging, a high dose is typically necessary, with strength ranging between 10 kGy up to 60 kGy to maintain the sterility of the product. For the list of packaging materials and their respective maximum dose, you may check it on the FDA website.

CONSUMER AWARENESS

It is so normal for almost anyone to think negatively whenever they hear the word “radiation”. Well, it is a common knowledge that exposure to radiation may lead to discomfort and even long-term health effects such as cancer. For this reason, consumer groups have voiced against the use of radiation to treat foods. But what is the truth? Is food irradiation different and safe?

Change in sensory characteristics

Do irradiated foods differ in terms of sensory quality?

Well, according to the FDA, irradiation does not change the food’s texture, taste, and appearance. However, even though the process is minimal, noticeable changes may occur depending on the radiation dose and temperature and the food itself.

Here are a couple of studies.

This 2017 Brazillian study determined the influence of irradiation using gamma rays on the physical and sensory properties of two rice cultivars. The study involved doses up to 5 kGy. While the lowest dose of 1 kGy received good acceptability, other samples received lower scores due to undesirable yellowing, and the development of burnt and bitter taste.

This 2019 study evaluated the sensory, physicochemical, and the shelf life effect of irradiation on strawberries at doses of 0.5 and 1 kGy. Gamma radiation at 1.0 kGy resulted in loss in weight and firmness, thus accelerated aging. But gamma radiation at 0.5 kGy did not affect the sensory properties and maintained color and taste until the 10th day of observation. The shelf life of control samples was 7 days.

While many fruits and vegetables respond positively to irradiation at appropriate doses, not all are suitable for the treatment. Some react to the process adversely and exhibit undesirable changes in taste, texture, and color, hence limits consumer acceptability. The time of harvest and physiological state also affect the outcome of the treatment. For example, some fruits such as strawberries do not develop the desirable ripe color if irradiated before are they ripe.

Effects on nutritional value

Food irradiation is a cold process. Therefore, nutrients that are lost are significantly less than those other methods that involve elevated temperature such as canning and pasteurization. Even in high-dose irradiation, the nutrient loss is very mineral, and even comparable to other methods of preservation such as freezing. The losses in nutrient are even lower in low-dose irradiation.

Extensive researches have shown that the macronutrients carbohydrates, proteins, and fats are barely affected by irradiation at usual doses. Similarly, minerals that include calcium, phosphorus, and iron do not show significant depletion by irradiation.

While macronutrients and minerals show little losses to irradiation, vitamins have varied sensitivity to the process. This depends on the food and the solubility of the vitamin in fat and water. For example, one research showed that vitamin B1 (thiamin) in aqueous solution suffered 50% loss at 0.5 kGy. While the same vitamin at the same dose only lost 5% in dried whole egg. One way to minimize vitamin loss is by freezing the food prior to irradiation or by packing the food under nitrogen. Other inert gas will also do.

Along with B1, the vitamins A (retinol) C (ascorbic acid), and E (a-tocopherol) are particularly sensitive to irradiation.

The actual amount of nutrient loss depends on several factors such as the irradiation dose, temperature, packaging, storage time, the presence of oxygen, and the food composition. However, since irradiation of most food products does not involve doses higher than 10 kGy, researchers have focused on the effect on vitamins at lower doses.

Health and radiolytic products

The ions and radicals involved in food irradiation may react with the components in the food. The radiolytics effects may lead to chemical transformations— the so-called “radiolytic” products.

The main reported radiolytic products are some cholesterol oxides and furans, and hydrocarbons and 2-alkylcyclobutanones (products of fat-containing irradiated food.) The International Consultative Group on Food Irradiation also reported “familiar” radiolytic products. These included formic acid, glucose, and acetaldehyde. However, these products or compounds are not new at all. And in fact, the formation of these are not limited to food irradiation— either naturally found in food or products of other food processing methods, particularly heat treatments.

What consumers fear are these unique radiolytic products, particularly those that could make the cells to stop functioning, injuring the cell membrane and the DNA (genetic mutation). Actually, irradiation creates several thousands of compounds. And some of them may be those that pose a long-term hazard (carcinogens), as what some critics believe.

The critics and those oppose the idea of food irradiation even presented over 400 studies that showed the possible adverse effects on human health, particularly carcinogens. However, the FDA dismissed all but 5 of these as they were scientifically flawed. The 5 studies showed that food irradiation is safe. Still, experts say extensive research is necessary.

Although existing researches have shown that consuming irradiated food does not cause observable negative short-term effects. The safety of irradiated food has been assessed through animal diet. However, studies observed no genetic effects in the subjects either. Therefore, the safety in the long run can not really be accurately concluded. Long-term effects may be observed if one consumes large amount of irradiated food. But this is not the case since diet typically includes small servings of irradiated food.

Organizations on food irradiation

Today, through extensive researches, the following organizations have identified food irradiation a safe process:

- Disease Control and Prevention (CDC)

- Codex Alimentarius Commission

- FAO

- FDA

- IAEA

- Scientific Committee of European Union

- WHO (World Health Organization)

METHODS OF DETECTION OF IRRADIATED FOODS

To implement proper quality control of irradiated foods, a reliable detection method has to be in place. Most methods rely on detection of radiolytic products, the presence of free radicals, the microbial load, modification of the DNA, carbohydrates and amino acids, and other similar methods. Here are a few.

Electron spin resonance (SR) spectroscopy

Electron spin resonance (ESR) spectroscopy detects radicals such as crystalline sugar and cellulose radicals, products of irradiation. These radicals in food are very stable in solid components, such as bones. Hence, bone-containing products like meat, poultry, and fish are ideal for this method. Since the 1950s, ESR spectroscopy has been used to detect radiation-induced free radicals. However, ESR spectroscopy is not ideal for foods with high moisture content since radicals disappear quickly. The process is relatively simple, specific and rapid. But what limits this method is the cost of ESR spectrometers.

Thermoluminecence (TL)

The method of detection of irradiation by TL is based on the emission of light; heating the food releases the energy trapped in the crystalline lattices. The lattices may be contaminated with sand and other crystalline materials. Examples of these minerals are those in fruits and vegetables such as berries, herbs, and spices as well as those in the intestines of seafoods, particularly shellfish. Wet sieving and treatment with a high density liquid removes and isolates the adhering minerals from the foods. A sensitive photon counter measures the energy released in the form of light. This method of detection has been official control analysis of irradiated food in Finland since 1990. For more on this method, visit the International Atomic Energy Agency (IAEA) for the document from the University of Helsinki.

Detection of radiolytic products

Although many radiolytic products also form in other types of food processing, those that form as a result irradiation have a distinct distribution pattern.

2-alkylcyclobutanones are major products of fatty acids in irradiated foods. Others that have been detected are 2-alkyl cyclobutane, n-alkane and n-alkene, esters, lactones, ketones, and other hydrocarbons. Studied have revealed that their levels increase with radiation dose and temperature.

Radiolytic products, particularly 2-alkylcyclobutanone, do not form as a result of degradation. Using gas chromatography and mass spectrometry to detect these can be a positive marker if foods, especially fat-containing ones, have been irradiated. Other methods of detection of radiolytic products in foods include high pressure liquid chromatography, thin-layer chromatography, and supercritical fluid extraction.

Biological load profiling

It is true that all food processing methods, including irradiation, reduce the microbial population. However, some microorganisms are more resistant to radiation. This research studied the effects of gamma radiation on pathogenic bacteria. At low radiation doses of 0.11 Gy to 0.44 Gy, results indicated that Gram-positive bacteria are more resistant to radiation than Gram-positive bacteria. Other studies have shown similar results.

Based on the established fact that Gram-negative bacteria are more sensitive to radiation, the main focus of early studies was on Gram-negative bacteria. For example, one study showed that the microbial profile of one raw chicken meat involved a significant number of Gram-negative bacteria, the genus Pseudomonas in particular. However, after irradiation at 2.5 kGy, the flora that developed on a raw chicken was primarily Gram-positive bacteria.

The Limus Amoebocyte Lysate test in conjunction with Gram-negative bacteria count, estimates the reduced viability of microorganisms after irradiation. Partnered with Direct Epiflourescent Filter Technique (DEPT), it provides the number of microorganisms eliminated by irradiation. Exceeding the DEPT count by 104 or higher is an indication that the food has been irradiated.

FOOD LABELING AND THE RADURA SYMBOL

Like any other forms of food products, irradiated foods are monitored and regulated.

Consumers can tell if one is irradiated food by carefully reading the label. Whole food that has been irradiated must bear the radura symbol and then the phrase “treated by irradiation” or treated with radiation”.

Some products that have not been treated with radiation only have irradiated ingredients. If this is the case, the special labeling requirement is not necessary on the package.

However, the special labelling is required for products that are not yet in the market, but may undergo further processing. This is to ensure that the products are not irradiated multiple times. If this is the case, the FDA advises to include and state the reason of the irradiation.

Because the words “radiation” and “irradiation” are usually associated with the negative connotations, the food industry has been pushing to use alternative words such as “electronically pasteurized” and “cold pasteurized” on the label. However, doing so is one way of misleading the consumers. Because by definition, pasteurization is the method of heating liquids for the purpose of making it safe for consumption. Irradiation, on the other hand, uses ionizing radiation, such as gamma rays and e-beams— totally different approach to food preservation.

KEY TAKEAWAYS

- Food irradiation is a process that utilizes ionizing radiation to kill spoilage and pathogenic bacteria to extend the shelf life of food.

- Food irradiation is also effective in inhibiting sprouting in vegetables, delaying ripening in fruits, preventing insect infestation in crops, and sterilizing packaging materials.

- The sources of radiation are gamma rays, x-rays, and electron beams.

- The maximum absorbed dose delivered to a food should not exceed 10 kGy, unless necessary.

- At appropriate doses, irradiation does not affect the food’s sensory properties.

- The effect of ionizing radiation in nutrients is very minimal; however, some vitamins may be vulnerable to the treatment.

- Food irradiation is a safe treatment; various organizations that include the FDA, WHO, and the Scientific Committee of European Union recognize its safety.

- The radura symbol and the phrases “treated by irradiation” and “treated with radiation” indicate that the product has been irradiated.

Other references:

R. L. Singh, S. Mondal (2019). Food Safety and Human Health. Academic Press

D.A.E. Ehlermann (2014). Encyclopedia of Food Safety. Academic Press

P. Fellow. (2000). Food Processing Technology (2nd Edition). Woodhead Publishing Limited