When you indulge in a piece of chocolate, you probably don’t give much thought to the ingredients that go into making it. However, one ingredient that you may come across in the list of chocolate additives is polyglycerol polyricinoleate, commonly known as PGPR. This tongue-twisting compound plays an essential role in the production of chocolate and contributes to its smooth texture and mouthfeel.

In this article, we will explore what PGPR is, how it is made, and its significance in the world of chocolate.

Table of Contents

WHAT IS POLYGLYCEROL POLYRICINOLEATE?

Polyglycerol polyricinoleate or PGPR is a food emulsifier derived from the seeds of the castor oil plant. With its excellent emulsifying properties, PGPR effectively combines fat and water-based ingredients, ensuring they remain mixed without separation. In chocolate production, PGPR plays a crucial role in creating a desirable smooth and creamy texture by effectively binding cocoa solids and cocoa butter together.

As an emulsifier, PGPR is denoted by the E number E476.E numbers are codes for substances used as food additives in the European Union. In the region, PGPR is permitted in cocoa-based confectionery and chocolates up to 5 g/kg.

HOW IS IT MADE?

Castor oil, which is produced from the seeds of the castor plant (Ricinus communis), is the primary source of PGPR. The oil contains ricinoleic acid, a fatty acid that undergoes esterification. Esterification is a chemical process that occurs when an organic acid (RCOOH) reacts with an alcohol (ROH) to produce an ester (RCOOR) and water.

In the instance of PGPR manufacturing, ricinoleic acid interacts with glycerol, a trihydroxy alcohol, to generate polyricinoleate. The hydroxyl (-OH) groups in glycerol are substituted with the carboxylic acid (-COOH) groups of ricinoleic acid during this process. Polyglycerol is then created by polymerizing glycerol molecules, which entails connecting glycerol units to form chains of variable lengths. The polymerization process is typically catalyzed by an acid catalyst or enzymes.

You might also like: White Vs. Dark Vs. Milk Chocolate: Which Melts The Fastest?

The final step involves combining the polyricinoleate and polyglycerol. The polyglycerol chains intertwine with the polyricinoleate chains, forming a complex structure. This combination enhances the emulsifying properties of the final product.

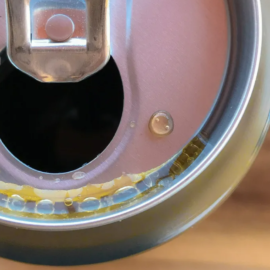

The resulting PGPR is a yellowish, viscous liquid with excellent emulsification capability.

FUNCTIONS OF POLYGLYCEROL POLYRICINOLEATE (PGPR) IN CHOCOLATE

One of the most commonly used ingredients in chocolate is lecithin, which acts as a food additive to reduce viscosity, improve flow properties, and extend the shelf life of chocolate. However, many chocolate manufacturers prefer to use PGPR due to its lower cost compared to lecithin. Lecithin is a naturally sourced emulsifier typically extracted from soybeans and, to a lesser extent, from eggs. However, the extraction and refining processes for lecithin can be more complex, requiring additional steps. Similarly, cocoa butter, another commonly used emulsifier, is also expensive. By opting for PGPR instead of lecithin, chocolate manufacturers can reduce production costs without compromising the overall quality of the chocolate.

Viscosity control

During chocolate manufacturing, PGPR helps control viscosity, the resistance of a fluid to flow. Chocolate needs to flow smoothly during various production steps, such as tempering, molding, and coating. Proper viscosity allows for easier handling and manipulation of the chocolate, ensuring efficient and consistent production. Here is an example.

During the tempering process, chocolate is heated and cooled to specific temperatures to ensure the cocoa butter in the chocolate crystallizes properly. Properly tempered chocolate has a glossy appearance, a smooth texture, and a snap when broken.

Now if the viscosity of the chocolate is too low or runny, it becomes challenging to handle and manipulate. The chocolate may flow excessively, making it difficult to control during pouring, molding, or coating.

It may spread too thinly when poured into molds, resulting in uneven or fragile chocolate shapes. Similarly, when coating items like truffles or nuts, the thin chocolate may not adhere properly, resulting in inconsistent coatings.

On the other hand, if the viscosity of the chocolate is too high or thick, it becomes stiff and less fluid. This can impede the flow of chocolate during production processes. It may be challenging to pour the chocolate into molds or spread it evenly during coating. This can lead to irregular shapes, uneven coatings, and an overall unappealing appearance of the final product.

By incorporation PGPR during the manufacturing, the viscosity is controlled. Hence, the chocolate flows smoothly and consistently. This results in consistently shaped chocolates, uniform coatings, and an aesthetically pleasing final product. A 2013 study determined a 0.5% lecithin and 0.1% PGPR is best for viscosity and yield point for chocolates.

Emulsification

The main reason why PGPR is added to chocolate is because of its emulsification property.

We know that water and oil are two liquids that do not mix well, right? Well, ingredients in chocolate are no different.

Chocolate is a complex mixture of fat (cocoa butter) and water-based ingredients (sugar, cocoa solids, milk solids, etc.). These components have different polarities and do not naturally mix well. Without an emulsifier, the fat and water phases in chocolate would separate, resulting in an unstable and unappealing product. This is where PGPR functions.

PGPR’s emulsification effectiveness is attributed to its molecular structure, which provides a balance between hydrophilic and hydrophobic characteristics. This allows it to interact with both fat and water components, facilitating their dispersion and creating a stable emulsion.

PGPR works by reducing the surface tension between the fat (cocoa butter) and water phases in chocolate. The molecule contains hydrophilic (water-loving) polyglycerol chains and hydrophobic (fat-loving) polyricinoleate chains. When added to chocolate, PGPR orients itself at the interface between the fat and water phases. The hydrophilic polyglycerol chains of PGPR interact with the water molecules present in the chocolate, while the hydrophobic polyricinoleate chains interact with the cocoa butter, which is the main fat component. This dual interaction helps to create a stable and uniform emulsion.

This results in a homogenous mixture.

Preventing fat bloom

Preventing fat bloom is a secondary effect of PGPR’s emulsification properties. Fat bloom occurs when chocolate is exposed to temperature fluctuations, causing the cocoa butter to migrate to the surface, resulting in a whitish or grayish discoloration.

When chocolate is heated, the cocoa butter melts, resulting in fat bloom. As the fat melts, it uses capillary action to travel and migrate through the chocolate structure’s microscopic channels and gaps. This movement of melted fat inside the chocolate matrix can result in an uneven distribution of fat, giving rise to fat bloom.

Once the temperature decreases, the melted cocoa butter begins to solidify again. However, since the fat has moved and settled on the surface due to its migration, it recrystallizes there. The recrystallized fat forms a separate layer on the surface, giving the chocolate a whitish or grayish appearance.

By introducing PGPR into chocolate, the risk of fat bloom is reduced since it improves fat dispersion inside the product. This is accomplished by decreasing the surface tension of the fat and other chocolate ingredients. As a result, cocoa butter can diffuse more uniformly throughout the chocolate, lowering the possibility of fat migration and subsequent bloom production. Although PGPR is important in minimizing fat bloom, other factors such as storage conditions, temperature variations, and the specific chocolate formulation can all have an impact on the occurrence of bloom.

This blog post discusses more about fat bloom.

SAFETY OF PGPR TO HUMAN HEALTH

Many consumers are wary about the safety of food additives, especially if they seem more “chemical” than natural. And PGPR is no exception. PGPR is a synthetic compound, which can lead to skepticism about its safety compared to natural ingredients. However, it’s crucial to remember that not all synthetic substances are automatically harmful, and that includes PGPR.

And here’s why.

PGPR is approved for use as a food additive by regulatory agencies worldwide, including the U.S. Food and Drug Administration (FDA), the European Food Safety Authority (EFSA), and other relevant authorities.

These agencies have reviewed the scientific evidence on PGPR and determined that it can be used safely in food products. To investigate the safety of PGPR, numerous toxicological studies have been undertaken. These studies looked into potential side effects such as acute toxicity, genotoxicity, carcinogenicity, and reproductive toxicity.

In one study, the carcinogenic potential of PGPR was assessed in rats and mice. For 80 weeks, 25 male and 25 female mice were fed diets containing 5% PGPR or groundnut oil. There was no evidence that PGPR causes cancer. PGPR also had no deleterious effects on growth, food intake, lifespan, or blood health.

Studies involving human subjects

During the mid 1960s, a study of PGPR involving human subjects was conducted. PGPR was consumed at levels up to 10g/day for 2 weeks. The study found no consistent adverse effects on various biochemical parameters, as well as no toxic effects on the liver and kidneys. These results indicate that the consumption of PGPR, even at higher quantities than typically consumed, does not have adverse effects on human health.

Consistent findings from various studies support the conclusion that PGPR does not present substantial risks to human health when consumed within approved limits. Regulatory bodies such as the FDA and the Joint FAO/WHO Expert Committee on Food Additives (JECFA) have established the Acceptable Daily Intake (ADI) for PGPR at 7 mg/kg body weight per day. In Europe, the European Food Safety Authority (EFSA) has set a higher ADI for PGPR at 25 mg/kg body weight per day. The ADI represents the maximum amount that can be safely consumed daily over a lifetime without causing adverse effects.

CONCLUSION

In conclusion, polyglycerol polyricinoleate (PGPR) is a food emulsifier derived from the seeds of the castor oil plant. It plays a crucial role in chocolate production by effectively binding cocoa solids and cocoa butter together, creating a smooth and creamy texture. PGPR controls viscosity, ensuring the chocolate flows smoothly during various production steps. It also acts as an emulsifier, preventing the separation of fat and water-based ingredients in chocolate, resulting in a stable and uniform emulsion. Moreover, PGPR helps reduce the likelihood of fat bloom, which can occur due to temperature fluctuations.

Regarding safety, regulatory agencies such as the FDA and EFSA have deemed PGPR safe for consumption within approved limits. Studies involving human subjects have found no adverse effects on health even at higher consumption levels. The ADI for PGPR has been established to ensure its safe use in food products.

Overall, PGPR is a valuable ingredient in chocolate manufacturing, contributing to its texture, stability, and overall quality.