Aspergillus species play a less significant part in the production of fermented foods (at least in foods popular in Western cultures). But they are still a component of some of the fermented foods that are consumed the most around the world. One example of important specie in food is Aspergillus oryzae (A. oryzae). A. oryzae is a filamentous fungus (a mold), also known as “koji” mold, commonly used in Chinese, Japanese, and other East Asian cuisines.

Its primary uses include fermenting soybeans to produce soy sauce and miso (fermented bean paste). It is also used to sweeten rice, barley, other grains, and potatoes to produce alcoholic beverages like hōchū, huangjiu, sake, and makgeolli (Korean rice wine). Billions of people actually consume these Asian fermented foods.

In Japan, this mold is culturally important. In the journal of the Brewing Society of Japan, Dr. Eiji Ichishima of Tohoku University referred to the koji fungus as a “national fungus” (kokkin). This is due to its significance in the production of koji for miso, soy sauce, and a variety of other traditional Japanese foods in addition to koji for sake brewing.

You might also like: What Is Dark Soy Sauce?

Studies suggest that the Japanese domesticated Aspergillus flavus. A. flavus is a pathogenic fungus that produces aflatoxins. But what the Japanese used mutated to stop producing the aflatoxins. This eventually gave rise to the beneficial A. oryzae mold.

Let’s discuss further the Aspergillus oryzae genome as well as its various uses in food.

ASPERGILLUS ORYZAE: THE KOJI MOLD

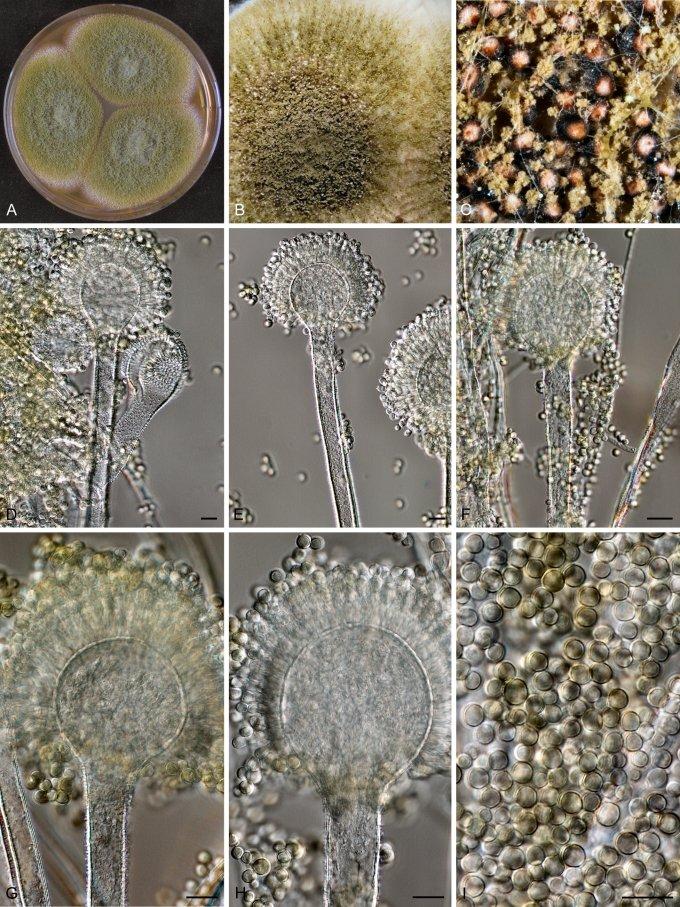

A. oryzae or simply Koji mold, is an aerobic filamentous fungus in the Aspergillus subgenus Circumdati section Flavi. Aspergillus section Flavi also contains industrially important species such A. flavus and A. parasiticus, both of which generate aflatoxins.

While closely related to other Aspergillus species, A. oryzae does not produce aflatoxins. Rather, the ability of Aspergillus oryzae to ferment makes it an important fungus in food manufacturing. In fact, the Food and Drugs Administration (FDA) has listed it as Generally Recognized as Safe (GRAS).

A. oryzae grows best at 89°F (32°C) to 97°F (36°C), and cannot grow over 111°F (44°C). It prefers a pH of 5 to 6 for growth, and can germinate in pH between 2 and 8. Aspergillus Oryzae has been observed to grow in dry food, such as corn flour with a water content of about 16%. It can grow on media with a water activity (aw) greater than 0.8, although it rarely grows below 0.8.

A. oryzae haploid genome contains 37 million base pairs and 12,000 predicted genes organized into 8 chromosomes. A consortium of Japanese biotechnology companies revealed this information in late 2005.

A. oryzae‘s genome is one-third larger than the genomes of two related Aspergillus species, the genetics model organism A. nidulans and the potentially deadly A. fumigatus. Many of the additional genes found in A. oryzae have been linked to secondary metabolism. The sequenced strain, RIB40 or ATCC 42149, was obtained in 1950. The specific increase of genes for amino acid metabolism, secretory hydrolytic enzymes, and amino acid/sugar uptake transporters make A. oryzae an ideal microorganism for fermentation.

SOY SAUCE MANUFACTURING

Soy sauce is a dark brown liquid that is made by fermenting soybeans and wheat in a salt brine. Manufacture starts with the preparation of raw materials. Soybeans or defatted soybean flakes are cooked after being moistened. For each form of soy sauce, the cooked beans are mixed with toasted, cracked wheat in varying proportions.

Soybeans are cooked in a continuous cooker at high temperature and pressure for a short period of time. In koikuchi, usukuchi, and saishikomi shoyu soy sauce manufacture, the same amount of cooked soybeans and roasted wheat is blended. And then the mixture inoculated with an A. oryzae or Aspergillus sojae pure koji starter. Certain Aspergilli species are also utilized in the production of usukuchi and shiro shoyu to prevent the formation of a deep color in the following steps of fermentation.

You might also like: Saccharomyces Cerevisiae Yeast In The Food Industry

After three days of fermentation, a 17% to 19% salt solution is applied to the koji (fermented grains) to create liquid mash called moromi. During the moromi process, osmophilic lactic acid bacteria and yeasts provide a distinct taste, scent, and color in moromi. High concentrations of proteins and carbohydrates from raw materials are significantly destroyed by koji enzymes and microbial action.

To ensure homogenous conditions and accelerate microbial growth, the moromi mash is occasionally stirred and aerated. Lactic acid bacteria, such as Pediococcus soyae or Lb. delbrueckii are permitted to grow on the moromi to make it acidic enough to prevent spoilage and sour taste. Afterwards, yeasts like Saccharomyces rouxii and Torulopsis sp. grow on the moroni to produce alcohol and aid in flavor production. The moromi process takes 4 to 8 months to complete, depending on temperature, agitation, and air supply from an air compressor.

SAKE FERMENTATION

Alcoholic beverages from East Asia are very distinct, compared to those of Western origin. It is because of two reasons. First, their main ingredient is fermented starchy grains, usually rice. Another reason is that fermentation does not occur from grain enzymes into sugars. Instead, a mold is introduced to start the fermentation process in unison with yeasts. A good example of a product that is produced by this is Japanese sake (rice wine).

This alcoholic beverage is transparent, pale yellow. The substrate food is steamed rice starch, which is hydrolyzed to sugars by Aspergillus oryzae to produce the koji. In general, whole or brown rice is milled to remove 25% to 50% of the surface material (germ and bran), which is required because the fat and protein components are undesired. The rice is then rinsed and steeped for several hours to reach a moisture content of about 30%. The damp rice is then cooked for an hour and chilled to 86°F (30°C) to 95°F (35°C). Three-quarters of this rice are removed and chilled to 41°F (5°C) to 50°F (10°C) for later use. The final fourth is utilized to make koji.

Saccharomyces sake ferments the substance for 30-40 days, giving in a product with 15-20% alcohol and roughly 0.3% lactic acid. The main fermentation takes place in open tanks under cool circumstances, starting at around 50°F (10°C) and rising to around 59°F (15°C). S. cerevisiae strains used in sake production differ from those used in wine and beer production. They have greater osmotic, acid, and ethanol tolerance.

Following fermentation, moromi is separated from the solids to create clarified saké, which is settled, refiltered, pasteurized, mixed, and diluted with water before bottling.

MISO MAKING

Miso originated in China and Korea thousands of years ago. But Japan is today’s leading producer and consumer. Miso is a popular fermented soy bean product. If you have not tasted one before, miso tastes just like soy sauce, but liquid or paste-like, and with a texture similar to that of thick peanut butter. It is used in Japan to make soups and broths. It is also used as a seasoning or flavoring agent. Products similar to miso include doenjang (Korean bean paste), taoco (Indonesian bean paste), and taosi (fermented black soybeans from the Philippines).

Miso is manufactured in a manner similar to that of soy sauce, with one notable exception. Dry salt, rather than brine, is added straight to the koji-soy bean mixture during miso production. For this reason, the product has roughly double the total solids of soy sauce (50% to 60% against 24% to 28%).

The production process begins with the manufacture of koji. Rice, barley, or soybeans can be used as substrate. At 59°F (15°C), the rice or barley is soaked in water overnight before steaming in a batch or continuous cooker. After cooling, a spore culture of specific strains of Aspergillus oryzae and A. sojae is utilized as the inoculum at 0.1%. The koji is then cultured in fermentation chambers at 86°F (30°C) to 104°F (40°C) for 40 to 48 hours.

After that, miso is made by combining salt, koji, steamed soybean, and water, and adding the halo-tolerant yeast, Zygosaccharomyces rouxii or Candida versatilis. The salt is then added to help the yeast and LABs ferment and to prevent any unwanted form of fermentation.

The mixture is allowed to mature for three to twelve months.

References:

M. Shafiur Rahman (2007). Handbook of Food Preservation (2nd edition). CRC Press.

R. Hutkins (2006). Microbiology and Technology of Fermented Foods. Blackwell Publishing.

J. Jay, M. Loessner, D. Golden. (2005). Modern Food Microbiology (7th edition). Springer.

M. Gibson (2018). Food Science and the Culinary Arts. Academic Press.

B. Ray (2005). Fundamental Food Microbiology (3rd edition). CRC Press.

G. Cooper (2018). Food Microbiology. Library Press.

Y. H. Hui (2012). Handbook of Plant-Based Fermented Food and Beverage Technology (2nd edition). CRC Press.