Non-thermal based processing methods like high-pressure processing (HPP) are relatively novel techniques. Thermal-based ones have been used for the long time. But these non-thermal based techniques have been recently garnering attention in the food industry because they are able to preserve food while minimizing the loss of quality.

In this blog post, we’ll discuss the specifics of high-pressure processing. We’ll discuss how it works, its benefits, and its applications in the food industry.

What is high-pressure processing?

As the name suggests, high-pressure processing in a type of food processing method wherein extremely high pressure is used to eliminate harmful microorganisms and preserve the food. This type of processing method is innovative because it does not use heat or chemicals. The latter, in some instances, is not favorable because it can cause undesirable changes like browning or nutrient degradation. This is why high-pressure processing is desirable in certain food products like fruits, vegetables, and other perishable items.

The first high-pressure processed foods were fruits kiwi, strawberries, and apple jams, all of which produced by Meidi-ya Food Co., Japan. The color and taste of the jams was natural.

It is worth noting though that although HPP can prolong shelf life, it does not pasteurize food. That means after processing, the food must be kept at refrigeration temperature. This is especially true for low-acid foods like milk, vegetables, and soups. High-pressure processed food can last up to 120 days or 4 months.

HPP-made food products can more costly than used produced using other methods, mainly heat treatments. The factors that contribute to this include the especial packaging requirement, lower production capacity, and low market demands. All of this are which are expected for novel technologies. However, consumers may benefit from extended shelf life, quality, and the value-added products, which cannot be achieved with other processing methods.

Today, HPP is used mainly on food products with high moisture contents such as ready-to-drink meats, seafood, fruit juices, and prepared vegetables. HPP is not as effective in dry products because moisture is necessary to carry out the process.

How does it work?

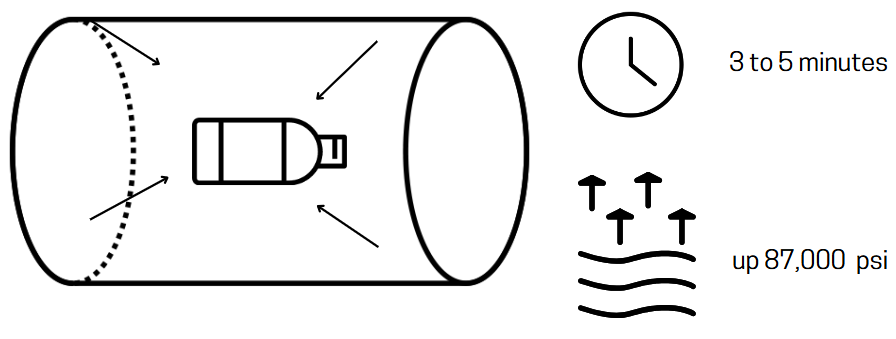

HPP involves subjecting the food at extremely high hydrostatic pressure. Prior to this, the food is usually packed in a highly flexible sterile packaging container. And then, it is put in a chamber where it is pressurized. The pressure employed varies and can reach up to 87,000 lb per square inch (psi) for 3 to 5 minutes. This pressure that hits the food is uniform on all the sides. For this reason, the shape of the food is retained—not damaged or squished.

You might also like: How Osmosis Preserves Foods (And How Microbial Cells React)

How high-pressure processing works depends on the Le Chatelier’s Principle. According to this, any reaction or change or phase transition with an increased in volume will be favored at high pressures, and reactions that involved an increase in volume will be inhibited. However, because many food systems are complex, the changes and reactions that can occur under high pressure can be difficult to predict at times.

Fortunately, recent progress on research and study about HPP has led to knowing the various effects of high pressure on chemical and enzymatic reaction, microbial inactivation, and nutrient retention.

In terms on biological retention, for example, the membrane of the microorganism is the most probably area for disruption. Furthermore, high-pressure can also inactivate key enzymes, particularly those involved during DNA replication and transcription. The combination of these factors is lethal to vegetable microorganisms.

Why high-pressure processing?

HPP is similar to other kinds of processing methods—they destroy harmful microorganisms and extend the shelf life of various products. But as I have already mentioned, HPP can be a much better option for a few reasons.

HPP merely depends on high pressure to do its job. Hence, there is no covalent bonds that are broken during processing. When broken, covalent bonds tend to produce free radicals or chemical by-products. Free radicals are highly reactive molecules because they contain an unpaired electron. Prolonged exposure to free radical can be harmful to human health because they can damage cells and DNA.

Because HPP does not produce free radicals, HPP practitioners do not require approval from the Food and Drug Administration (FDA) and Food Safety Inspection Services to operate.

Another reason HPP can be a better option is nutrient retention. It is just one of the few non-thermal processes that do not use heat to process food. Other similar methods include osmotic dehydration, irradiation, and pulse electric fields.

HPP is particularly beneficial in processing foods that contain vitamin B, C, and antioxidants lycopene and beta carotene. These are nutrients that degrade at high temperatures. This behavior is demonstrated in this study, wherein strawberry and blackberry purees produced by HPP reduced antioxidant activity by only 5%, whereas thermally processed ones reduced by 25%.

References:

V. Vaclavik, E. Christian (2014). Essentials of Food Science (4th edition). Springer.

S. Rahman (2007). Handbook of Food Preservation(2nd edition). CRC Press.

R. Rajenran, A. George, N. Kalarikkal, S. Thomas (2019). Innovative Food Science and Emerging Technologies. CRC Press