The global population is growing at an increased rate since 2000. As of this writing (06/2022), Earth is home to an estimated 8 billion people, according the United Nations. The number will continue to swell at 8.5 billion by 2030, and increase even further at 10 billion by 2050. Of course, this means more mouths to feed. But how are we going to answer the demand for more food, especially meat? Meat needs to be strategically addressed for some reasons. In Western countries, meat is stable at 30% part of the diet. In developing countries, the rate of consumption of meat is soaring. Animals such as cows and pigs for meat require more resources, including feed, water, fuel, and land. To make things worse, the pressure on these things are steadily climbing.

So livestock raising may not be a sustainable long-term solution to satisfy the demand for meat. One solution to this predicament is cultured or lab meat. To be clear, cultured meat is meat made from real animal. Cultured meat is produced by cultivating animal (typically cow or pig) cells and growing them in a lab. But why cultured meat? There are many answers to this question, really. But in terms of sustainable, cultured meat helps eliminate the need to raise, slaughter, and process farm animals.

The first edible lab grown meat was produced in 2013 by Mark Post in a form of beef burger patty. The patty cost $330, 000 and took a couple of years to produce. Well, unsurprising for a food produced by a relatively novel technology. In 2020, start-up company Eat Just, sold the first ever lab-grown chicken meat ‘chicken bites’ in Singapore. The production of this cultured meat only takes 14 days, 31 days faster than traditionally raised chickens. And it only costs $17!

Table of Contents

HOW CULTURED MEAT IS PRODUCED

Since the cultured beef patty in 2013, many start-up companies have entered the cultured meat market. Today, various cultured meat products are being developed. At the start of 2021, 60 start-up companies had been established worldwide.

Presently, the cultured meat technology is still at an early stage. For this reason, several factors have to be addressed. First, there has to be a high level of consumer acceptance. The product’s color, taste, texture, and palatability have to be similar to that of conventionally grown meat. Another factor is how to bring the market price down to be affordable. Although efforts have been made since 2013 to make this possible.

So how exactly is cultured meat produced?

Muscle harvesting

Cultured meat is made from real animal. The production starts by obtaining muscle sample from the animal. From here, the stem cells in the sample obtained are extracted. The stem cells are the body’s special raw materials because they have the ability to self renew. This means they have the potential to divide and develop into different types of cells (muscle and fat cells, for example). In this case, they are the ones that will be grown into meat. Harvesting stem cells is primarily performed through biopsy on an animal under anesthesia. Alternatively, stem cells can also be sourced from cryopreserved cultures (frozen cultures obtained from a previous research).

You might also like: Food Trends: These Are The Foods Of The Future

Stem cell culturing

After the stem cells have been successfully extracted, they are placed in a petri dish and immersed in a culture medium to allow them to proliferate and multiply. The culture medium is carefully formulated to contain the necessary nutrients, including carbohydrates, proteins, and fats. In some formulations, the culture medium may contain additives such as steroids or special proteins for additional growth factors.

The optimal medium is known to contain fetal bovine serum (FBS), a serum derived from the blood of a deceased calf that is rate-limiting. Using this specific culture medium, over one trillion cells are able to grow. The fibers that form are connected to a sponge-like structure that provides nutrition and mechanically stretches them. This increases their size and protein content.

Here’s what exactly happens during culturing:

The cells consume the nutrients from the medium. When the nutrients are sufficient, they start to divide and their population increases in an exponential manner.

As the muscle fibers begin to contract, the pH level or acidity drops because of the lactic acid accumulation. The pH of the growing environment must be at the optimum to allow the cells to absorb nutrients and proliferate. To keep the environment’s pH and nutrient concentration in control, the culture medium is replenished regularly.

Placing stem cells on scaffolds

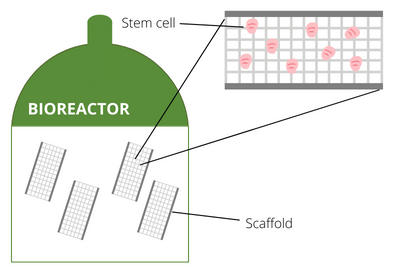

Then, the stem cells are placed on scaffolds, which are then placed in a bioreactor. Scaffolds are predominantly animal-derived, collagen and gelatin, for example. They are made of biodegradable and edible materials for the safety of the consumer. Scaffolds are molds that encourage and facilitate the growth of the cells into muscle fibers. They achieve this by manipulating the growing tissue’s geometry as well as the cell type distribution. Additionally, scaffolds also play a part in ensuring sufficient distribution of nutrients and oxygen.

Scaffolds come in different forms. The simplest is microcarriers. They allow efficient scale up of adherent cells. Another type is porous scaffold, which is economical to use. It provides a stable structure for cell growth, and the distribution of pore sizes can be adjusted to concurrently bias cellular differentiation in the desired direction while still allowing for adequate oxygen, nutrition, and waste transport. 3D bioprinting scaffold provides defined structures at various dimensions with precise control over cell and bioink positioning. This work discusses scaffolds in more detail.

You might also like: Myoglobin: The Protein That Dictates Meat Color

Cells into meat

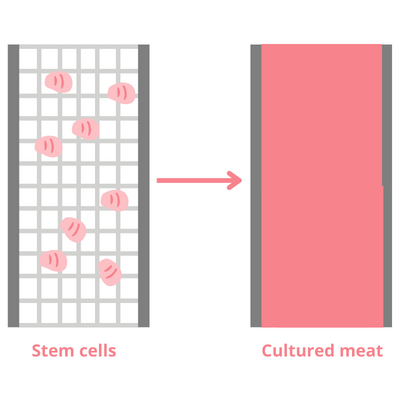

Producing cultured meat continues in a bioreactor. A bioreactor is a large vessel or machine in which environmental factors such as temperature and pH are controlled to optimize cell growth (proliferation or differentiation). At this point, while bathed in a nutrient liquid in the bioreactor, cells grow into sheets of meat. Since they are thin, the sheets require processing into larger pieces.

There are two ways of cultivating cells: continuous and batch systems. In a continuous system, there is a continuous procedure of inoculating and harvesting cells to ensure that cells are always present in the bioreactor. Whereas in batch systems, cells are inoculated, cultured, and harvested all in the same period.

Cultured meat processing

The resulting cultured meat sheets are then removed from the bioreactor. They are processed into thicker slices to mimic real meat. Depending on the product, additives such as fat, flavorings, and colorings are mixed to produce a product that looks and tastes like traditionally grown meat.