Powdered milk, alternatively termed dried milk or milk powder, undergoes a processing method where the liquid component is extracted, resulting in a finely textured powder. In the United States, it must not exceed 5% moisture by weight. This powder can be reconstituted with water to yield a liquid milk suitable for consumption. Valued for its prolonged shelf life, convenient storage, and adaptability in diverse culinary and food manufacturing uses, powdered milk holds significance in various applications.

HOW IS IT MADE?

The process commences with the collection of fresh milk from dairy farms, typically sourced from cows, though other mammalian sources may also be utilized. After collection, the liquid milk undergoes a dehydration process, primarily achieved through techniques such as spray drying or roller drying.

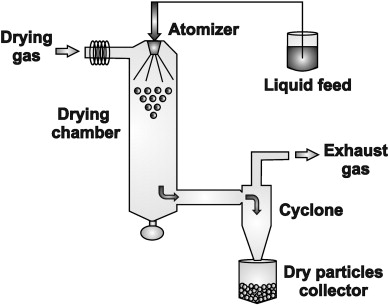

Spray drying

The first step in spray drying involves preparing the milk by homogenizing it to ensure a uniform mixture. The liquid milk is then pumped through a specialized nozzle, breaking it into tiny droplets. These droplets are introduced into a drying chamber, where they come into contact with hot air. The heat causes the moisture in the droplets to evaporate quickly, leaving behind dried particles of milk solids. The size of the resulting powder can be controlled by adjusting the spray nozzle and regulating the drying conditions. This allows manufacturers to produce a range of powdered milk products with varying textures and applications.

Preserving nutritional content stands out as a primary benefit of utilizing spray drying in the production of powdered milk. This method is specifically engineered to reduce heat exposure, safeguarding essential nutrients like proteins, vitamins, and minerals from degradation. This ensures the maintained nutritional value of the end product.

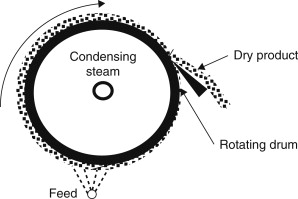

Roller drying

Roller drying, also known as drum drying, is an alternative method for producing powdered milk. It is also used for the manufacturing for other dehydrated flakes and powders. In this process, liquid milk is applied onto the surface of a heated drum or roller. As the drum rotates, the milk spreads thinly and is simultaneously exposed to hot air, leading to the evaporation of moisture and the formation of dried milk solids.

The roller drying technique imparts distinct attributes to the produced powdered milk. The steady rotation of the drum ensures a uniform and consistent heat exposure, facilitating a controlled drying process. The resulting milk powder exhibits a flaky or sheet-like texture, proving advantageous for recipes that require specific textures. However, when compared to spray drying, roller drying might involve slightly elevated temperatures, potentially resulting in the loss of some heat-sensitive nutrients.

One notable aspect of roller drying is its suitability for specific types of milk-based products. For instance, roller drying is often preferred for the production of instant or quick-dissolving milk powders. The resulting flakes or sheets can be easily broken down into a fine powder that quickly dissolves when reconstituted with water.

FORTIFICATION

The production of powdered milk, while offering practical advantages, carries the potential for unintended consequences. The widely utilized methods of spray and drum drying, while efficient in dehydrating liquid milk, can unfortunately compromise the stability of certain heat-sensitive nutrients. This is where fortification comes in.

Fortification in food refers to the intentional addition of essential nutrients, such as vitamins and minerals, to enhance the nutritional content of a product. This process aims to address nutritional deficiencies, meet specific dietary requirements, and provide consumers with a more comprehensive and healthful food option. In the case of powdered milk, common fortifications include vitamin D, calcium, and vitamin A.

You might also like: What Is Fortified Milk?

The fortification process is not arbitrary; it is intricately regulated to meet specific nutritional standards. Regulatory bodies establish guidelines to ensure that fortified powdered milk provides a consistent and reliable source of essential nutrients.

This precision in fortification not only compensates for potential nutrient losses during production but also aligns the powdered milk with established nutritional benchmarks. This reassures consumers of its reliability as a convenient and nutrient-rich alternative to fresh milk. In the US, the quantity of vitamin A and D, if included, must not be less than 2,000 and 400 International Units per quart, respectively.