Here is one thing that is so true—everybody loves desserts. And top of everybody’s list is ice cream. According to World Atlas, New Zealand consumes the most ice cream per capita at 28.4 annually, the United States comes in second at 20.8, and Australia at 18.0. We can’t blame them, though. Who can’t resist that sweet, creamy frozen dessert? The reason for the desirable characteristics of ice cream lies beyond how it is made.

There are several different kinds of edible ice, which are simply blends of water, sugar, flavorings, and additional ingredients that are partially frozen then beaten to create a stiff foam. In most types, milk or cream is a key component. Many types of ice cream contain dairy products such as cream, skim milk, sweet cream buttermilk, or sweetened condensed milk, as well as optional caseinates.

Let’s take a look closer at how ice cream is made through science.

ICE CREAM IS MADE UP OF A MIXTURE OF SOLID, LIQUID, AND GAS

For the many of us, ice cream is merely a frozen bowl of cream. But no, ice cream is one of the many examples of emulsions. Emulsions are mixtures of liquids that do not normally mix, oil and water for example. (We will talk about emulsifiers in ice cream further in this blog post.) Instead, the liquid gets dispersed throughout the other liquid. In the case of ice cream, the mixture is made up of three phases: partially frozen milk fat and ice (solid); unfrozen cream and water (liquid); and trapped pockets of air (gas).

Milk fat and ice

The frozen fat globules and ice water are the solid ingredients in ice cream. They are dispersed throughout the liquid phase of sugar water and cream. These components are typically unstable. But the application of emulsifier prevents them from collapsing into solid and liquid phases.

You might also like: How Salt And Ice Bath Freezes Ice Cream Faster

Fat contributes to flavor by giving the tongue a creamy sensation and sweetness. Additionally, they are partly responsible for the freezing-point depression and the increase in viscosity. The protein is important for the creation of fat-globule membranes during homogenization and partially assists in stabilizing the foam lamellae during air incorporation. Low temperatures can cause lactose to crystallize.

Ice crystals are essential for the right consistency and coolness in the mouth. Moreover, the low temperature causes the sweetness to be less intense. Small crystals should form in order to avoid sandiness. The quicker the freezing, the smaller the crystals. Cooling should occur quickly to prevent temperature swings and large crystal formation.

To reduce the price of ingredients, whey components are frequently used to replace a portion of milk solids that are not fat. In some countries, vegetable fats, including palm kernel oil that has partially undergone hydrogenation, are frequently used in place of milk fat.

Air

Air makes up a significant portion of ice cream, making this dessert a foam as well. In fact, air makes up up to 50% of the final volume! Ice creams are sold by volume though. But if you try weighing a liter of ice cream, you would probably get only about 500 grams. But the thing is that air contributes to what makes ice cream desirable—light, soft, and fluffy.

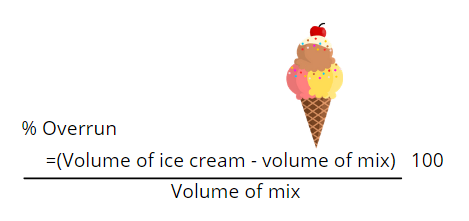

In commercial ice cream making, overrun refers to the increase of volume due to incorporation of air in the mixture during freezing. Typically, ice cream overrun range between 60 to over 100%. 100% overrun means half of the ice cream’s volume is air. To make ice cream more affordable, manufacturers tend to exceed 100% overrun. One downside of this is that ice cream melts more readily. Overrun can be calculated by the following formula:

Ice cream can be found in a bewildering array of grades and styles. The best ingredients are used in superpremium and premium ice cream, which has a low overrun and a high fat content. Gelato resembles frozen ice cream but has more fat and little to no overrun. Soft serve ice cream has up to 60% air overrun and is low in fat (3 to 6%). Compared to superpremium or premium ice cream, standard ice cream contains more overrun (air).

EMULSIER IS A KEY INGREDIENT

We have already learned that ice cream is not a solid frozen foam. Instead, it is a mixture of three phases of solid, liquid and gas.

These three phases mix with one another to create a colloid. A colloid is a mixture with characteristics of both homogeneous and heterogeneous mixtures. A closer look at it, it is a microscopically dispersed mixture in which dispersed particles do not settle out. In the case of ice cream, it is both an emulsion and a foam, both of which can be described as a colloid.

You might also like: Emulsifiers In Food: What Are They?

The solid phase of frozen fat globules and ice water spread across the liquid phase of sugar water and cream in ice cream is normally unstable. If kept that way, the mixture will only separate into two phases of fat and water. To prevent this from happening, ice manufacturers use emulsifiers. Emulsifiers are the additives or agents that act as a bridge between the phases of fat and water. Ice cream has a variety of various stabilizers and emulsifiers.

The mouthfeel and creaminess of the ice cream depend heavily on the ratio of each colloid phase. If there is too much fat, the ice cream will have the consistency of butter; if there is too much sugar or milk solids, the ice cream will be weak; and if there are too few crystals, the ice cream will not get crunchy.

Here are some examples of emulsifiers in ice cream.

The majority of ice creams contain stabilizing emulsifiers to reduce the growth of fat and ice crystals, which lessen the flavor of ice cream.

Alginate is a frequently used to lessen the production of ice crystals. It is sourced out of the cell walls of algae. Alginate has a lot of —OH functional groups and can easily form hydrogen bonds with water to bind it. Alginate’s significant hydrogen bonding restricts water movement and creates a gel that serves as a thickener.

The structure of the water-carbohydrate complex also prevents ice crystals from forming. Many foods substitute carrageenan, a cell wall carbohydrate from red algae (seaweed), with alginate.

Polysorbate 80 is another typical ice cream emulsifier. This complex carbohydrate is attached to a long unsaturated fatty acid. It is used in ice cream at fairly high concentrations to keep the ice cream scoopable. While the fatty acid tail of Polysorbate 80 binds hydrophobically with the fat globules, the carbohydrate component of the molecule interacts with water and protein. The water and fat phases are kept together by this covering. This post discusses emulsifiers in ice cream in more detail.

ICE CREAM MANUFACTURING

Now that we have discussed the science of ingredients in making ice cream, let’s discuss the manufacturing process.

The first stage of the manufacture is composing the ice cream mix. The additives include emulsifier, stabilizer, and flavor and color substances. Then, the mix is subjected to pasteurization, homogenization, cooling and holding (for aging), and quick freezing.

Pasteurization

With the ingredients prepared, they are pasteurized. Pasteurization minimizes the risk of disease and extends the shelf life of milk. It is a mild heat treatment (176°F for 25 seconds for ice cream) of a product for it to be safe for human consumption. It achieves its objective by primarily killing pathogenic and spoilage microorganisms.

Since lipase (fat) is still somewhat active even at very low temperatures, inactivating it is the second key goal of the process. Therefore, bacterial lipases ought to be avoided. Lipase is an enzyme, or a special protein that speeds up the rate of many reactions. This naturally occurring enzyme in milk produces flavor molecules that are desirable in cheese making, but only produce rancidity (oxidation of oils or fats in food science) in ice cream making.

You might also like: UHT And Pasteurized Milk: What’s The Difference?

Finally, pasteurization makes the mix more desirable, especially for hardened ice cream, because it decreases the product’s susceptibility to autooxidation. Food products that have undergone autooxidation lose their nutritious value and develop distinctively unpleasant and off flavors.

Homogenization

Homogenization’s main purpose is to stop creaming, or the rise of fat to the top of the milk container. In the case of ice cream, the process aims to provide the ice cream mix a sufficiently fine, smooth texture and slow melting properties. This is achieved by shrinking the size of the fat globules to create a stable emulsion of the fat. Hence, homogenization is a must for ice cream that contains fat.

The mixture should homogenize at the pasteurizing temperature. At any given pressure, the elevated temperature results in more effective breaking up of the fat globules, and also lessens fat clumping. However, the excessive formation of homogenization clusters should be prevented. This will only make the ice cream mix excessively viscous and the desirable fine texture will not form.

You might also like: What Is Homogenized Milk?

Several factors affect the effectiveness of homogenization. The homogenization pressure should be adjusted based on the amount of fat, the level of pasteurization, and, if necessary, the mix’s additional composition. For example, the pressure for high-fat ice cream should be low. Reduced pressure lessens the chance of cluster formation, especially for ice cream mixes with more than 15% fat. High pressure during homogenization produces a more stable emulsion as well as smaller fat globules, which is ideal for low-fat ice cream.

Cooling and ripening

Storing ice cream at a low temperature for some time is for two reasons. Before the ice cream mix goes into the freezer, the majority of the fat in the fat globules should have crystallized. This is where cooling at 39.2°F (4° C) does its job. It is important to note that due to the small size of the fat globules, there may be significant undercooling. Another reason for ripening at low temperature is that some emulsifiers require considerable time at low temperature to displace protein from the fat globules. Furthermore, some stabilizers, such gelatin and locust bean gum, take a long time to swell after being dispersed.

Freezing

This is quick freezing. Slow freezing creates larger ice crystals, and that is not ideal. As air is beaten in, ice is created. This has to occur concurrently. After most of the water is frozen, any beating in of air becomes harder to achieve. After the air has been beaten in, the foam structure can be damaged by freezing because it causes insufficient churning of the fat globules. Additionally, the strong beating promotes quick chilling, which allows for the formation of tiny ice crystals.

You might also like: Why You Should Not Freeze Meat At Home

In constantly operating machinery, mix and air are introduced into the equipment in specified volume quantities. This allows the overrun to be precisely regulated, while a stirrer shrinks the air cells. The manufacturing procedure takes a short amount of time. At 38.3°F (3.5°C) to 44.6°F (7°C), the ice cream mixture comes out of the freezer.

References:

V. Vaclavik, E. Christian (2014). Essentials of Food Science (4th edition). Springer.

M. Wallert, K. Colabroy, B. Kelly, J. Provost (2016). The Science of Cooking: Understanding The Biology And Chemistry Behind Food And Cooking. John Wiley & Sons, Inc..

Pieter Walstra, J. Wouters, T. Geurts (2005). Dairy Science and Technology (2nd edition). CRC Press.

T. Britz, R. Robinson (2008). Advance Dairy Science and Technology. Blackwell Publishing.