Modified atmosphere packaging (MAP) is a special form of packaging wherein the internal package atmosphere is modified so that the gaseous composition differs from that of air, which is replaced with nitrogen and/or carbon dioxide. In most cases, the gas composition is 78.08 % nitrogen, 20.96 % oxygen, and 0.03 % carbon dioxide. But this still depends on the type of food product, the permeability of the packaging material, microbiological activity, and respiration of the food. High-fat products is best packed with carbon dioxide, whereas baked goods should be packed with nitrogen. High oxygen MAP (up 70% oxygen) is ideal for red meats as it helps retain the red color.

This packaging technology can be traced back in the 1800s when French chemist Jacques Étienne Bérard observed a delayed ripening process in fruits in an oxygen-depleted atmosphere. The Académie des Sciences awarded him a prize for being a pioneer in ripening of fruit study.

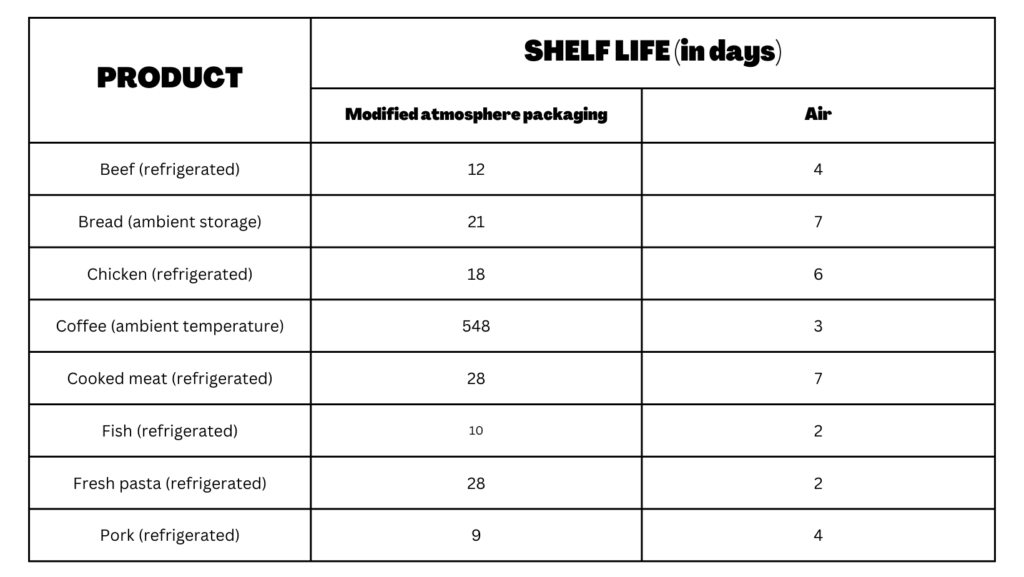

Today, MAP is a part of our daily life as it is employed for various foods—from fresh fruits to processed meats. So what does modified atmosphere packaging does, anyway? Well, MAP can effectively lengthen the shelf life by as much as 200%. It can also retain the quality and freshness of various food stuff, reducing the need for artificial preservatives or stabilizer.

Most minimally processed foods use MAP in combination with aseptic technology and refrigerated temperature. When used together with aseptic packaging, MAP becomes a more effective technology.

HOW MODIFIED ATMOSPHERE PACKAGING IS DONE

There are two methods of modifying the atmosphere within the package of a product: passive process and active process.

In the passive process (produce respiration), the generation of the modified atmosphere depends on the respiration of the produce. Respiration refers to the utilization of sugars in order to produce energy in plants. This is a continuous process even after harvest of fruits and vegetables. The product of respiration is carbon dioxide consumption and carbon dioxide liberation. The result of this is the gradual decrease in oxygen to the desired level as the level of carbon dioxide increases. The reduced respiration rate and conserved energy lead to extended shelf life. Since the passive process relies on produce respiration, it is a slow process that its benefits of MAP are not quickly realized. Fresh respiring fruits and vegetables are the most common application of this method.

You might also like: Ethylene And Ripening In Fruits And Vegetables

In the active process (gas flushing), on the other hand, a gas mixture of known concentration of oxygen, carbon dioxide, and nitrogen is flushed to the package headspace. This immediately suppresses ethylene and respiration. Before the gas flushing, a machine vacuums all of the air and toxic gases out of the packaging. And then through the same perforation, the gas mixture is flushed to the package.

THE ROLES OF OXYGEN, NITROGEN, AND CARBON DIOXIDE

The key to MAP’s effect is limiting the supply of oxygen while increasing the levels of carbon dioxide and/or nitrogen.

Oxygen

Oxygen has several ways of spoiling food. It is a highly a powerful oxidizing agent. When it reacts with certain compounds, it leads to deteriorative reactions. An example of this is browning reaction that occurs after cutting an apple. This change in color is a result of oxidation due to exposure of the flesh to air. Another degradative process that leads to losses in food quality is lipid oxidation. The presence of oxygen in fat-containing foods triggers a reaction that produces adverse effects, such as off-flavor, off-odor, and color change.

You might also like: The Reason Why Sliced Apples Turn Brown

Oxygen is one of the few requirements for microorganisms to survive. But this can be stopped by reducing the levels of oxygen inside the packaging and replacing it with carbon dioxide and/or nitrogen. The ability of aerobic spoilage bacteria to proliferate is slowed by the extremely low oxygen (usually 2%–3%) and moderately high carbon dioxide (5%–20%) levels present in a package, extending the shelf life of the product.

But there are some MAP applications wherein the oxygen levels are higher. An example of this is during packaging of unprocessed meats to maintain the red color of oxymyoglobin. Or to permit respiration of produce. By packing fresh red meat in a MAP of 80% oxygen and 20% carbon dioxide, the shelf life of the meat can be increased from three to seven days at 32°F (0°C) to 35.6°F (2°C). However, this could lead to issues with oxidative rancidity in fatty fish or the formation of off-colors in cured meats.

You might also like: Myoglobin: The Protein That Dictates Meat Color

Carbon dioxide and nitrogen

Carbon dioxide suppresses microbial activity in two ways. First, it lowers the pH of the product by forming mild carbonic acid when it dissolves in water in the food. And second, it has a negative impact on the enzymatic and biochemical processes that take place in the cells of both food and microorganisms.

To prevent rotting in fresh fruits and vegetables, a carbon dioxide concentration of 10% to 15% is needed. Some crops (such strawberries and spinach) can survive this level, but the majority cannot, making MAP inappropriate.

For processed (non-respiring) foods, the atmosphere should be oxygen at the lowest possible and carbon dioxide as high as possible without causing the package to collapse or changing the flavor or appearance of the product. Ground coffee is one of those that benefit from MAP. By packaging ground coffee in a MAP of carbon dioxide/nitrogen mixture, oxidation is prevented and the volatile aroma compounds are preserved.

You might also like: How Instant Coffee Is Made (And What Is Lost From Ground Coffee)

Nitrogen gas is common is processes that involve hermetic sealing of the package. This gas is tasteless, odorless, colorless, nonflammable, and nontoxic. And unlike oxygen, nitrogen is nonreactive with foods. So it offers protection from spoilage, oxidation, weight loss, dehydration, and freezer burn. In contrast to vacuum packaging, MAP uses high barrier film that prevents the modified atmosphere from escaping. With nitrogen, the package becomes pressurized, allowing it to stay loose-fitting. This avoids the skintight vacuum packaging, and prevents the packaging from collapsing. Nitrogen is the reason why snacks such as potato chips remain crispy.

However, there should be control over the degree of atmospheric modification. This is because there is a risk of physiological disturbances in the living tissues.

DISADVANTAGES OF MODIFIED ATMOSPHERE PACKAGING

MAP is widely used today because of its effectiveness in extending the shelf life of products while reducing the need for chemical preservatives. However, it has its downsides as well.

MAP works by reducing the levels of oxygen within the packaging materials. Although this slows down the growth of harmful microorganisms, it does not work well against anaerobic bacteria. These kinds of bacteria, particularly Clostridium botulinum, are capable of thriving without oxygen. Other microorganisms of concern in MAP-packed foods include Aeromonas hydrophila, E. coli, Campylobacter jejuni, Salmonella, and Listeria. To retard their growth, foods in MAP must have short storage times and be held at low temperatures. Controlling the water activity (at least 0.92 or lower) and using salt can also help.

The original gas composition in MAP gradually decreases over time, reducing its capability to protect the product against harmful elements. These depend on several actors such as product respiration, the load of aerobic and anaerobic bacteria, bacterial respiration, gas permeation via packaging materials/seals, temperature, light. Hence, choosing the right packaging material is important, in addition to proper storage and handling. Gas permeability and moisture vapour permeability are important parameters. Packaging materials for MAP are classified based on their barrier properties against oxygen.

| TYPE | BARRIER PROPERTY TO OXYGEN |

| Low barrier | >300 cc m -2 (For products where oxygen transmission is desired) |

| Medium barrier | 50–300 cc m -2 |

| High barrier | 10–50 cc m -2 |

| Ultra high barrier | <10 cc m -2 (Protects the product against oxygen to the end of its expected shelf life) |

If the packaging material is of poor quality, the nitrogen or carbon dioxide will be replaced with the surrounding oxygen through diffusion. If the packaging provides a strong barrier, the gases will stay inside the container for a longer amount of time, protecting the product.

References:

E. M. Yahia (2009), Modified and Controlled Atmospheres for the Storage, Transportation, and Packaging of Horticultural Commodities, CRC Press

V. Vaclavik, E. Christian (2014). Essentials of Food Science (4th edition). Springer.

J. Jay, M. Loessner, D. Golden (1994). Modern Food Microbiology (7th edition). Springer.

M. Shafiur Rahman (2007). Handbook of Food Preservation (2nd edition). CRC Press.

P. Fellows (2000). Food Processing Technology: Principles and Practice (2nd edition). CRC Press.

H. Ramaswamy (2015). Post-harvest Technologies of Fruits and Vegetables. DEStech Publications, Inc.