If you’ve just noticed Polysorbate 80 on a food label and are curious about its function, you’re not alone. Polysorbate 80 is a common food ingredient with numerous applications in the food business. It is a synthetic molecule with emulsifying capabilities created from sorbitol and oleic acid. It essentially allows the blending of materials that would normally separate, such as oil and water. Polysorbate 80, which is commonly found in processed meals, baked goods, ice cream, and salad dressings, serves an important role in providing a smooth and consistent texture in these products.

Let’s discuss further.

WHAT IS POLYSORBATE 80?

Polysorbate 80 is a versatile compound widely used in the food and pharmaceutical industries. It belongs to the family of polysorbate surfactants. This synthetic substance is derived from sorbitol, a sugar alcohol, and oleic acid, a fatty acid obtained from natural sources like olive oil. The resulting compound polysorbate 80, also known as Tween 80, exhibits exceptional emulsifying properties due to its unique chemical structure.

It is composed of a hydrophilic (water-attracting) polyoxyethylene chain and a lipophilic (fat-attracting) sorbitan ester chain, The lipophilic section, derived from sorbitan and oleic acid, anchors the compound within fat-based substances. This dual nature enables Polysorbate 80 to form micelles. These micelles are small structures in which the hydrophobic tails cluster together while the hydrophilic heads extend outward. This produces a stable emulsion. This property is particularly useful in the manufacture of smooth and consistent textures in items like ice cream, salad dressings, and baked goods.

Polysorbate 80 is assigned the European food additive number E433. The E numbers, or E additives, are codes for substances that are added to food for various purposes such as coloring, preservation, and emulsification. In the case of Polysorbate 80, its E number, E433, reflects its role as an emulsifier and stabilizer in food products.

HOW IS IT MADE?

The synthesis of Polysorbate 80 is a meticulously controlled, multi-step process. It begins with the esterification of sorbitol, a hexavalent sugar alcohol, using fatty acids derived mainly from natural oils such as olive oil. Esterification, a chemical process involving the reaction between an organic acid (with a carboxyl group, -COOH) and an alcohol (with a hydroxyl group, -OH), leads to the formation of sorbitan esters in the initial chemical reaction.

The sorbitan esters go through through ethoxylation, a key step involving the introduction of ethylene oxide under catalyst influence. The addition of ethylene oxide imparts hydrophilic (water-attracting) properties to the molecule, making it more soluble in water. Following this, purification steps employing distillation and filtration methods are implemented to remove any residual reactants and impurities. This is a critical step as the presence of impurities can affect the properties and performance of the final product.

The final manufacturing stage involves neutralization to attain the desired pH level. Polysorbate 80 is a nonionic surfactant, and its stability and effectiveness can be influenced by pH. Neutralization helps to stabilize the molecule and ensures that it remains compatible with a wide range of other ingredients commonly used in various products, including pharmaceuticals, cosmetics, and food.

FUNCTIONS IN FOOD

As emulsifier

In the emulsification process, Polysorbate 80 aligns at the interface between water and oil phases. The hydrophilic heads extend into the water, while the lipophilic tails immerse into the oil, creating micelles—tiny structures that encapsulate and disperse oil droplets within the water. This arrangement prevents the oil droplets from coalescing and separating, resulting in a stable and homogenous emulsion.

You might also like: Emulsifiers Used In Ice Cream

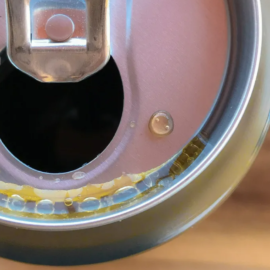

Polysorbate 80 is a common ingredient in baked goods, salad dressings, and ice cream. For example, it contributes to the smooth and creamy texture of ice cream, which enhances the desired mouthfeel. A complex blend of water, fat, sugar, and other substances makes up ice cream. These ingredients may have a tendency to separate in the absence of an emulsifier, giving the finished product an undesirable texture. Particularly the fat and water components naturally oppose one another, which leads to the production of ice crystals and an unsatisfactory consistency. Polysorbate 80 facilitates the coexistence of fat and water molecules by acting as a bridge. As a result, the ice cream keeps its uniform composition.

As anti-foaming agent

One of Polysorbate 80’s important properties is its capacity to lower surface tension, which aids in the destabilization of foam bubbles. Surface tension is a liquid attribute caused by the cohesive interactions between molecules at the liquid’s surface.

Foam is a mixture of gas bubbles scattered throughout a liquid or solid. Excessive foam can make industrial processes less effective. For example, uncontrolled foam formation in the food and beverage industry can result in uneven mixing, erroneous measurements, and variations in the quality of the finished product.

This is particularly true during mixing, blending, and cooking. For example, during the manufacture of candies and aerated treats, foaming may lead to the formation of undesirable air pockets in the final product. With the addition of Polysorbate 80, foaming is kept to a minimum during cooking, ensuring that confections set correctly.

Polysorbate 80’s anti-foaming properties also find application in the beverage industry, particularly in the production of carbonated drinks and beer. Excessive foam in these products can lead to inefficiencies in filling and packaging, as well as affect the sensory characteristics of the final beverage.

As wetting agent

Polysorbate 80 not only as an effective anti-foaming agent, and emulsifier, but also as a wetting agent (or surfactant). Wetting agents help overcome issues related to poor dispersion and solubility of certain components in food formulations. With its capacity to enhance the wetting properties of specific ingredients, Polysorbate 80 facilitates their seamless incorporation into food products. This property proves particularly beneficial in various applications, ranging from baked goods to sauces and dressings.

Flour, a fundamental ingredient in baking, tends to form clumps and resist hydration. Incorporating polysorbate 80 combats this issue by reducing the surface tension between flour particles and liquid components. This results in improved dispersion, allowing for a smoother, lump-free batter or dough. The even wetting of flour helps achieve a consistent texture and uniformity in the final baked product.

The versatility of Polysorbate 80 as a food additive makes it a preferred choice for manufacturers seeking multifunctional ingredients to streamline their processes. Its nonionic nature allows it to interact effectively with a diverse array of ingredients without compromising the sensory attributes of the final product.

SAFETY CONCERNS

After reviewing Polysorbate 80, the US Food and Drug Administration (FDA) declared it to be generally recognized as safe (GRAS) for use in a variety of food products at certain concentrations. This classification indicates that the use of Polysorbate 80 is thought to be safe for human consumption when used within certain bounds, according to the available scientific data.

Following thorough safety assessments, encompassing evaluations of genotoxicity, carcinogenicity, and developmental toxicity, the European Food Safety Authority (EFSA) established the Acceptable Daily Intake (ADI) for polysorbate 80 at 25 mg/kg body weight per day.

To guarantee safety, both the FDA and EFSA underscore the significance of following the recommended usage levels. For example, the maximum amount of polysorbate 80 permissible in ice cream is 0.1%.

Regulators have determined that Polysorbate 80 is safe, but some people may have mild side effects. Allergy-related side effects, like gastrointestinal distress or skin irritation, have been reported. These reactions, though, are usually uncommon and only happen to people with particular sensitivities. These adverse effects are marginally more likely to occur in people who take large doses of Polysorbate 80 or who are exposed for an extended period of time. It’s critical to be aware of these possible dangers, and to get medical help if you take Polysorbate 80 and notice any unsettling side effects.

It’s important to note that the majority of consumers can safely consume products containing Polysorbate 80 without adverse effects.